allen levine

Member

- Messages

- 12,365

- Location

- new york city burbs

Im building a small corner cabinet to hold a couple dozen liquor bottles.

Nothing fancy, Im not qualified to build anything that good, but its a box and it will be on legs.

I messed up already back from vacation one day and I already glued up the top the opposite way, with the ends front and back, not on sides.

(Ill make do, I dont want to waste wood)

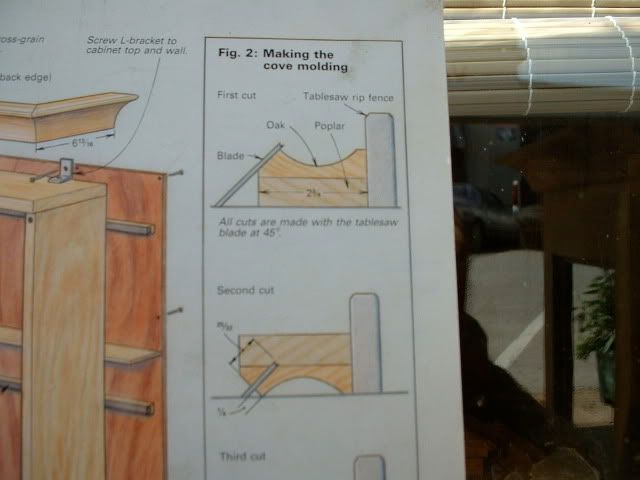

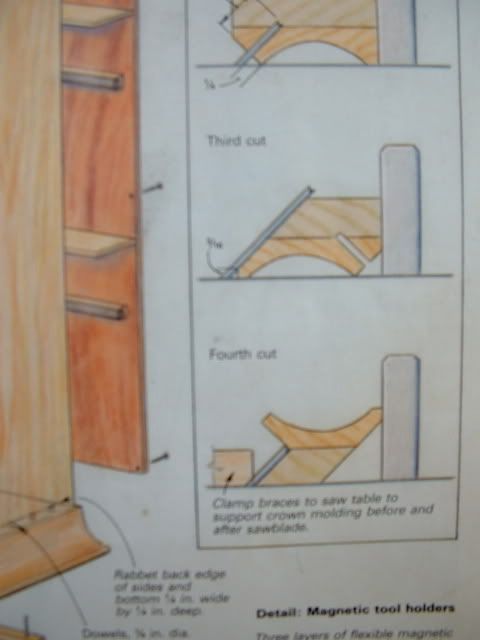

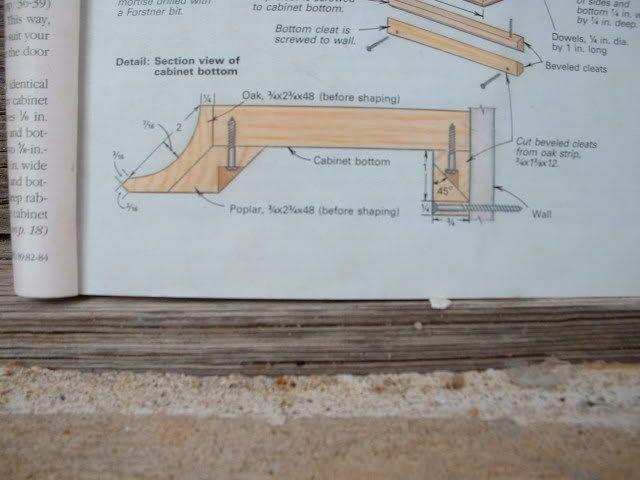

I want to use some 2.5 inch oak and cut a simple crown moulding on my table saw.

Couple questions. should I rout out a little design using the router first then run it through the table saw at somewhere around 40-45 degree angle cut?

Should I cut it first, then rout it, nothing fancy, maybe just one bit to give it adrop of shape, handheld router, so I cant do much fancy work.

Any suggestions on how to creat a simple crown molding to meet wall to top of cabinet would be appreciated.anyone whos done it and can show me a few steps, would be very helpful.

Nothing fancy, Im not qualified to build anything that good, but its a box and it will be on legs.

I messed up already back from vacation one day and I already glued up the top the opposite way, with the ends front and back, not on sides.

(Ill make do, I dont want to waste wood)

I want to use some 2.5 inch oak and cut a simple crown moulding on my table saw.

Couple questions. should I rout out a little design using the router first then run it through the table saw at somewhere around 40-45 degree angle cut?

Should I cut it first, then rout it, nothing fancy, maybe just one bit to give it adrop of shape, handheld router, so I cant do much fancy work.

Any suggestions on how to creat a simple crown molding to meet wall to top of cabinet would be appreciated.anyone whos done it and can show me a few steps, would be very helpful.

(but shes single, and shes still a firecracker)

(but shes single, and shes still a firecracker)