allen levine

Member

- Messages

- 12,370

- Location

- new york city burbs

My momma always told me never jump into the deep end of the pool first.

She was right.

I never listened.

I'm leaving for WNY tomorrow or next day(furniture delivery), and I've already contacted a supplier to put together an order of Ipe.

I wish I never met the stuff, but its beauty is something I cant get past.

My back let up a bit, and I've avoided all work, so I decided to spend a couple of hours drawing out a template,sketch for the chairs.

I make chairs. Lots of chairs. But I use screws and glue and screw the joints together.

Today, mortise and tenons, its another world.

A chair is for lack of a better word, unforgiving. Theres very little room for error, and Im quite sure the experts here know that.

Why I chose to build this way with zero experience in this joinery, noone around to help or suggest things, I dont know.

I can gather info from here, I hope once in a blue moon over this build someone will step in and steer me in the right direction if I stray too far.

This is going to be way above my skill level. I know chair makers might giggle at this, but this is by far the most difficult build I have ever tried.

This aint no cabinet.

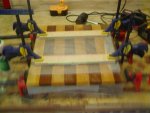

Cut some scrap 2x6s, made 2 legs, decided to just cut out half the mortises on each leg to see if I can make some tenons and see how this stuff works.

Laid the two back legs together before I marked them, nothing detailed here, this is scrap, so if Im off a tiny bit I wont lose sleep over it.

I have yet to build a simple tenon jig, that I will do before I cut another one.

It came together with the first few pieces I test fit, but man, this is very difficult stuff.

My intention is to cut every piece to size,(couple extra on slats and supports in case I cut errors with tenons somewhere along the way) then cut all the mortises, then cut each tenon, test fitting them on every piece, even though they should all be identical.(I might taper the front 2 legs and round over the top of the back, but wouldnt do that till all the mortises are cut first.)

She was right.

I never listened.

I'm leaving for WNY tomorrow or next day(furniture delivery), and I've already contacted a supplier to put together an order of Ipe.

I wish I never met the stuff, but its beauty is something I cant get past.

My back let up a bit, and I've avoided all work, so I decided to spend a couple of hours drawing out a template,sketch for the chairs.

I make chairs. Lots of chairs. But I use screws and glue and screw the joints together.

Today, mortise and tenons, its another world.

A chair is for lack of a better word, unforgiving. Theres very little room for error, and Im quite sure the experts here know that.

Why I chose to build this way with zero experience in this joinery, noone around to help or suggest things, I dont know.

I can gather info from here, I hope once in a blue moon over this build someone will step in and steer me in the right direction if I stray too far.

This is going to be way above my skill level. I know chair makers might giggle at this, but this is by far the most difficult build I have ever tried.

This aint no cabinet.

Cut some scrap 2x6s, made 2 legs, decided to just cut out half the mortises on each leg to see if I can make some tenons and see how this stuff works.

Laid the two back legs together before I marked them, nothing detailed here, this is scrap, so if Im off a tiny bit I wont lose sleep over it.

I have yet to build a simple tenon jig, that I will do before I cut another one.

It came together with the first few pieces I test fit, but man, this is very difficult stuff.

My intention is to cut every piece to size,(couple extra on slats and supports in case I cut errors with tenons somewhere along the way) then cut all the mortises, then cut each tenon, test fitting them on every piece, even though they should all be identical.(I might taper the front 2 legs and round over the top of the back, but wouldnt do that till all the mortises are cut first.)

Attachments

Last edited:

,

,