Frank Fusco

Member

- Messages

- 12,791

- Location

- Mountain Home, Arkansas

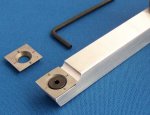

I have seen this discussed here but never really knew what it was. Looks like the end-all to lathe tools needed. I'm going to throw away all my lathe tools and make one of these.

Actually, I do plan to buy a set of the cutters and make one for myself. About $30.00 for ten cutters put on a homemade handle is a lot cheaper than $99.00, or more, from CS.

Watch the video. http://www.easywoodtools.com/

Actually, I do plan to buy a set of the cutters and make one for myself. About $30.00 for ten cutters put on a homemade handle is a lot cheaper than $99.00, or more, from CS.

Watch the video. http://www.easywoodtools.com/