Jason Vanick

Member

- Messages

- 25

- Location

- Cary, IL

I'll be interested to see what the software is capable of. In general, will it do more than just run the machine? Or does it include software that will render drawings/pictures in to cnc readable files (like http://www.vectric.com/ )?

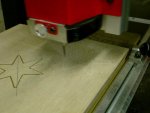

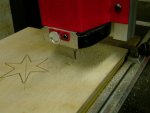

That's exactly what I use... I use VCarvePro from Vectric to make my designs.

There's 2 parts to the software needed to do cncing.

The most important part is the machine controller. It takes a "program" and tells the machine what directions to move and how fast. The most popular pogramming language is called 'gcode'... and the 2 most popular control applications are Mach3 (windows based, not sure how much it costs, maybe $150-$200) and EMC2 (linux based, free, source-code provided etc). I use EMC2 as my day job is working with Linux, Unix and other open-source applications.

The second part is something to transform files into gcode (or whatever programming language your machine uses). VCarvePro works really well for me and was extremely easy to learn how to use. It was well worth the $600 I spent on the license, probably even more so for the level of productivity that I've been able to achive (not to even mention the results which have been better than my wildest dreams for something that i built in the shop out of mdf

Typically if you buy a CNC, you get some kind of software app with it, and usually it does the functions of #1 and #2, if you're building your own, you really don't get that luxury.

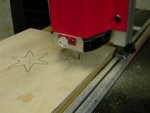

oh, I just realized that I don't have any pics of my dust collection setup for the cnc on my photo page, I'll upload a few in a few minutes. Dust collection is key for this as my router is usually making fine dust. I still need to ad a skirt around the base of it, but for now it works good enough.

we could start a new thread somewhere if people want to talk about building a cnc or operating a cnc, I'm not an expert (though I did stay in a Holiday Inn last night

-J