Dominic Greco

Member

- Messages

- 149

- Location

- Bucks County PA

Hi gang,

Here are some before and after shots of (2) Bedrock planes I refurbed this weekend.

One is an early "round sided" Bedrock 605 1/2 and the other is a Bedrock 606. As you can see, both were in somewhat rusty condition when I got them.

Bedrock 605 1/2: BEFORE

Bedrock 606: BEFORE

I soaked them in Evaporust for 24 hours. This is the first time I used that stuff and I have to say that it did make the clean up job easier. I still needed to hit a couple pieces with a brass wheel brush. But that was only because they were REALLY rusty. I will definitely use it again.

Evaporust bath:

After they were removed from the Evaporust, I washed them off with some mineral spirits. After they dried I buffed all the parts with a medium brass wire wheel brush. After that I gave all the parts a coat of 3-in-1 oil and allowed them to sit overnight. The next day (today) I ground a new bevel, flattened the back of the blade, and honed them. I also worked on the chip breakers. These were in Ok condition but needed to have the mating surfaces ground flat and the tops sanded smooth and buffed.

One side note here: Someone here suggested wiping down your stropping surface with mineral oil to help green honing compound adhere. Well, that worked GREAT and I have the cut up fingers to prove it! Man these blades are SHARP!

I tested them both out by squaring up a Cherry 4x4. While I like the way the 605 1/2 performed, I was most impressed with the 606. The mass of this fore plane really makes powering through tough job a breeze.

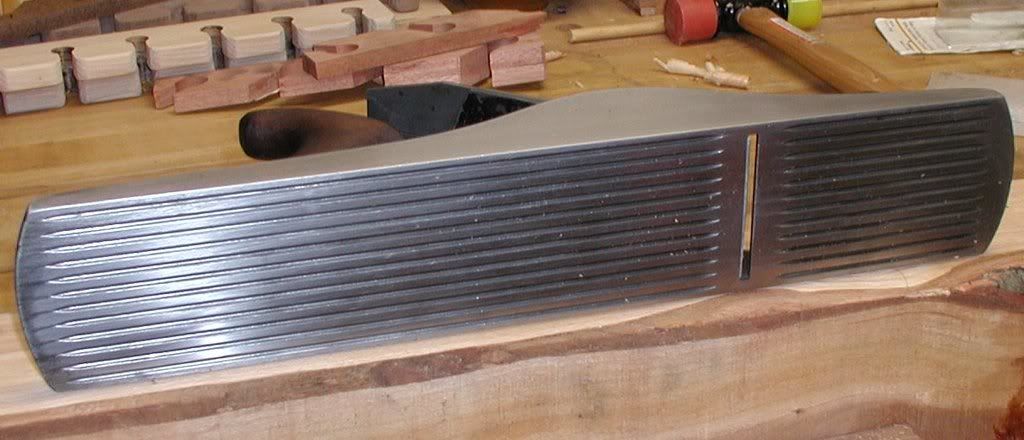

Bedrock 605 1/2: AFTER

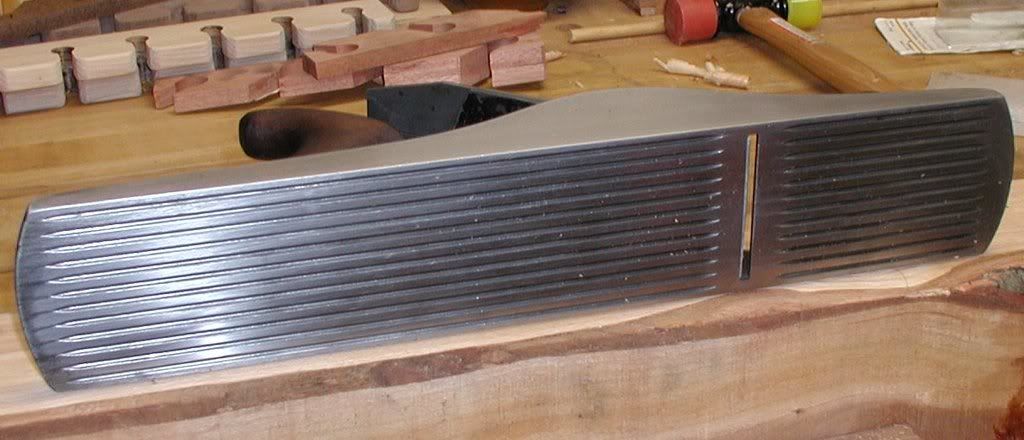

Bedrock 606: AFTER

Thanks for viewing!

Here are some before and after shots of (2) Bedrock planes I refurbed this weekend.

One is an early "round sided" Bedrock 605 1/2 and the other is a Bedrock 606. As you can see, both were in somewhat rusty condition when I got them.

Bedrock 605 1/2: BEFORE

Bedrock 606: BEFORE

I soaked them in Evaporust for 24 hours. This is the first time I used that stuff and I have to say that it did make the clean up job easier. I still needed to hit a couple pieces with a brass wheel brush. But that was only because they were REALLY rusty. I will definitely use it again.

Evaporust bath:

After they were removed from the Evaporust, I washed them off with some mineral spirits. After they dried I buffed all the parts with a medium brass wire wheel brush. After that I gave all the parts a coat of 3-in-1 oil and allowed them to sit overnight. The next day (today) I ground a new bevel, flattened the back of the blade, and honed them. I also worked on the chip breakers. These were in Ok condition but needed to have the mating surfaces ground flat and the tops sanded smooth and buffed.

One side note here: Someone here suggested wiping down your stropping surface with mineral oil to help green honing compound adhere. Well, that worked GREAT and I have the cut up fingers to prove it! Man these blades are SHARP!

I tested them both out by squaring up a Cherry 4x4. While I like the way the 605 1/2 performed, I was most impressed with the 606. The mass of this fore plane really makes powering through tough job a breeze.

Bedrock 605 1/2: AFTER

Bedrock 606: AFTER

Thanks for viewing!