Dan Mosley

Member

- Messages

- 1,169

- Location

- Palm Springs, Ca

I been still having tennon issues with them tearing out while turning.

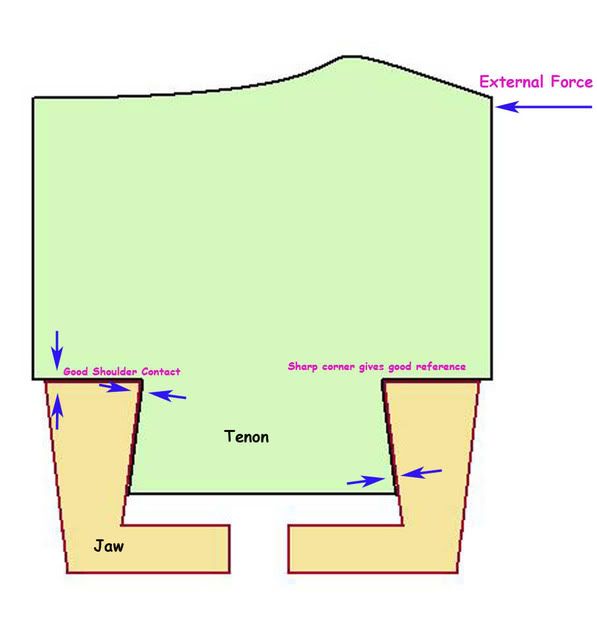

I did make the tennon shorter - not to short or the vessels/bowls with length wont hold - say about 1/4 inch or so ....but the spigot chuck has serrated teeth in it - i called Teknatool and talked to one of the guys that says the tennon "could" be longer if the wood were dry as the spigot chucks were designed to hold for vessels for hollowing without the tailstock support.

I dont think im over tightening but i do snug it down or with large bowls will come off,,

They said maybe my cuts are to aggressive - im using the Ci1 on the end grain hollowing so i dont think that is it.......

Back Ground:

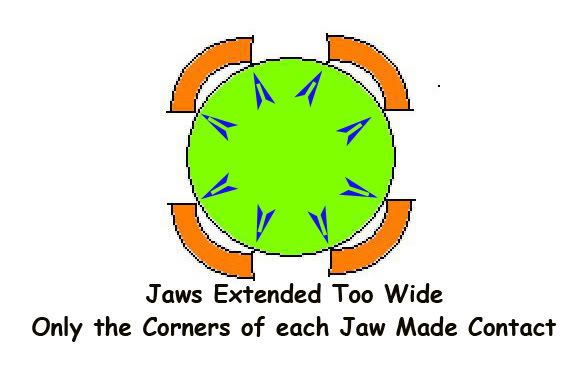

I have some logs of Hemlock and Doug Fur - very green still, i have them cut and anchor sealed.......my spigot jaws will open to 2 1/4 inch at max, and i use the tail stock to hold the other end when turning.

When the problem happens is always during the hollowing of the bowl. i cut around the tailstock and keep a tennon the inside as long as i can which helps alot but is kind of hard to work around but not impossible.....

When i examine the bowl and tennon after it tears out - it looks like it just shreads it - leading me to think the wood may wet and weak but i see others not having this problem. Other thing i notice is the tool will get small type catches when hollowing the end grain which causes me to sharpen my gouge often in hopes this will reduce the tension put on the tennon. Still I tear the tennon often

I have tried CA on the tennon prior to turning it but im not so sure that helps on wet wood....

i have tried glue blocks with hot glue (letting the gun get dripping hot), CA, titebond III (over nite drying time), they dont hold and im sure its from the moisture migrating back and loosening up the bond.

Proof was when i looked at the block after it came of - i noticed it comes off right at the glue line........

I keep thinking there is something im not doing as correctly as i should be so im comming back for more thoughts on what others think ?????

I did make the tennon shorter - not to short or the vessels/bowls with length wont hold - say about 1/4 inch or so ....but the spigot chuck has serrated teeth in it - i called Teknatool and talked to one of the guys that says the tennon "could" be longer if the wood were dry as the spigot chucks were designed to hold for vessels for hollowing without the tailstock support.

I dont think im over tightening but i do snug it down or with large bowls will come off,,

They said maybe my cuts are to aggressive - im using the Ci1 on the end grain hollowing so i dont think that is it.......

Back Ground:

I have some logs of Hemlock and Doug Fur - very green still, i have them cut and anchor sealed.......my spigot jaws will open to 2 1/4 inch at max, and i use the tail stock to hold the other end when turning.

When the problem happens is always during the hollowing of the bowl. i cut around the tailstock and keep a tennon the inside as long as i can which helps alot but is kind of hard to work around but not impossible.....

When i examine the bowl and tennon after it tears out - it looks like it just shreads it - leading me to think the wood may wet and weak but i see others not having this problem. Other thing i notice is the tool will get small type catches when hollowing the end grain which causes me to sharpen my gouge often in hopes this will reduce the tension put on the tennon. Still I tear the tennon often

I have tried CA on the tennon prior to turning it but im not so sure that helps on wet wood....

i have tried glue blocks with hot glue (letting the gun get dripping hot), CA, titebond III (over nite drying time), they dont hold and im sure its from the moisture migrating back and loosening up the bond.

Proof was when i looked at the block after it came of - i noticed it comes off right at the glue line........

I keep thinking there is something im not doing as correctly as i should be so im comming back for more thoughts on what others think ?????

Attachments

Last edited:

)

)