Reg Mitchell

Member

- Messages

- 328

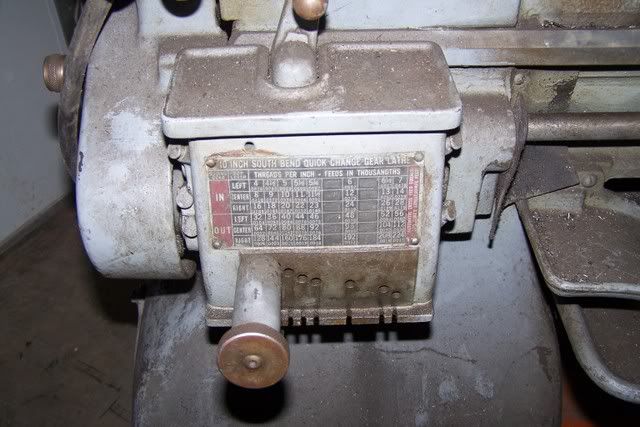

Sorry I beed lax guys but I have been busy with a mill rebuild. Didn't get any pic was in a hurry. I do have a South Bend lathe I am going through now. I am concentrateing on my machine shop this winter getting things ready for summer wood working. I have a list from the boss and it seems I am going to need a few things builte to complete her wished

Here's the project

Reg

Here's the project

Reg