- Messages

- 7,994

- Location

- falcon heights, minnesota

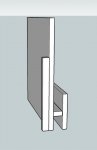

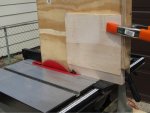

here's that jig. the tall board is the one you clamp your panel to, the smallest board is the stop block, and the other 2 are cut to fit your table saw's rip fence, so measure for a snug fit. just angle the blade to the angle you want, and keep the outer corner of the blade just proud of the board.