You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

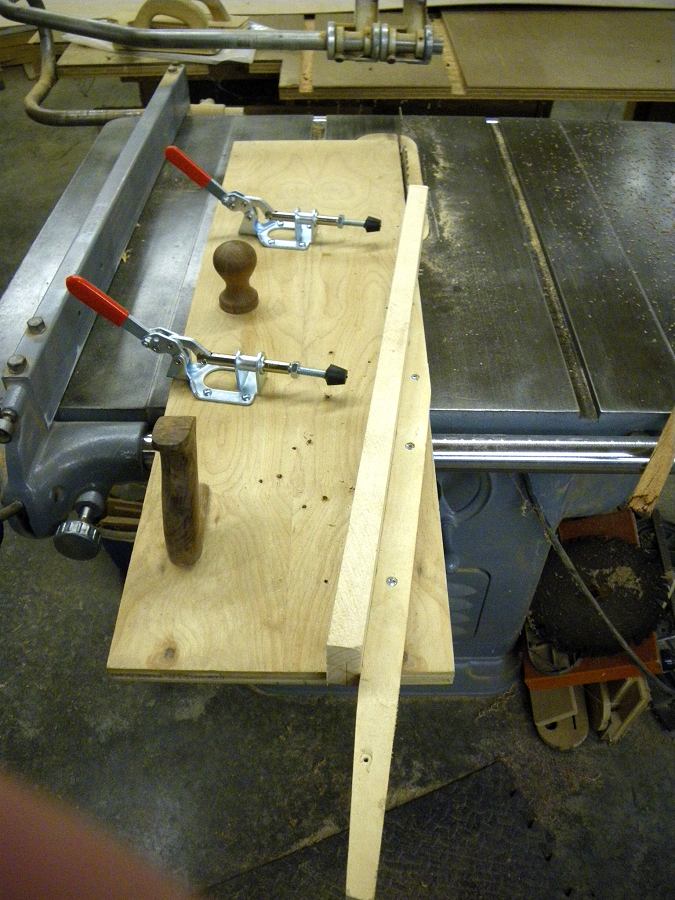

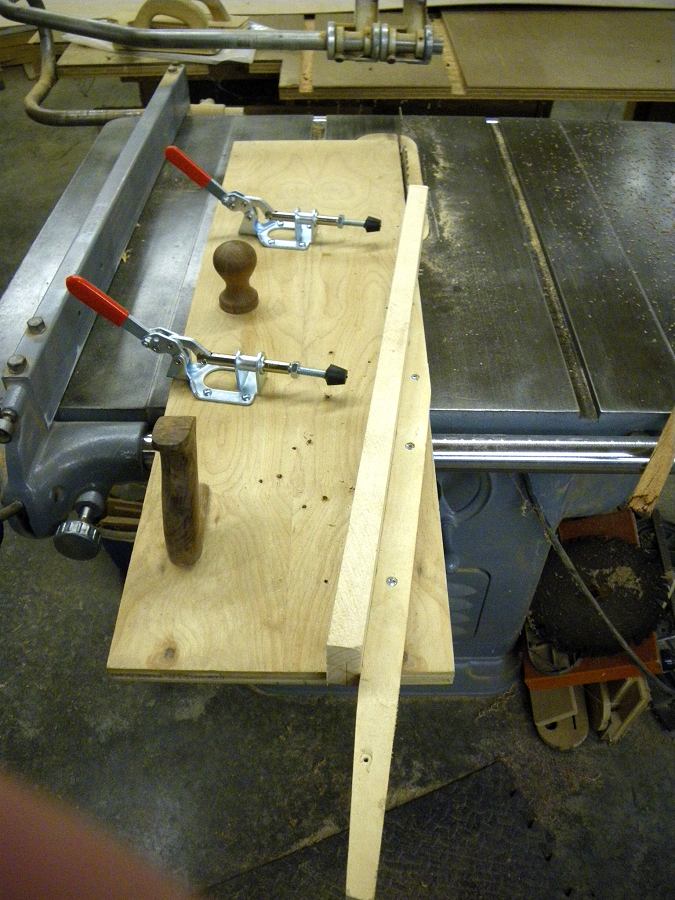

New scarfing jig * Version 3.0

- Thread starter Jeff Horton

- Start date

Mike Grimm

Member

- Messages

- 159

must...learn...sketchup!

Dave Richards

Member

- Messages

- 2,930

- Location

- SE Minnesota

Jeff, if you were to make the base wider as Vaughn suggested and continue the fence to the far side of the blade, you could add a simple hold down of masonite or plywood to the top of the fence to prevent the offcut from moving into the blade. Plane the top of the fence so there's a friction fit of the stock under the hold down.

You could also add a small feather board to that side of the fence to prevent the offcut from sliding back.

You could also add a small feather board to that side of the fence to prevent the offcut from sliding back.

Jeff Horton

Member

- Messages

- 4,272

- Location

- The Heart of Dixie

Dave, if you could hold the cutoff that would be good. But the problem is when you slide the sled back and the cutoff hits the saw blade. You have a sharp missile.

yes, you probably shouldn't slide it back till the blade stops but I did and I knew better. One moment of inattention.....

Stock height it not consistent enough. I use 1.5" and 2" stringers and rare times other sizes. So it's hard to make set height. I like the idea of a guard/sheild over the blade though. That could stop a missile attack. Just not sure how to do it and not have the cutoff resting on the sled.

Everyone on the other forums wants to do the same thing but I am convinced is just an accident waiting to happen. In my thumbs case, all ready happened.

yes, you probably shouldn't slide it back till the blade stops but I did and I knew better. One moment of inattention.....

Stock height it not consistent enough. I use 1.5" and 2" stringers and rare times other sizes. So it's hard to make set height. I like the idea of a guard/sheild over the blade though. That could stop a missile attack. Just not sure how to do it and not have the cutoff resting on the sled.

Everyone on the other forums wants to do the same thing but I am convinced is just an accident waiting to happen. In my thumbs case, all ready happened.

Dave Richards

Member

- Messages

- 2,930

- Location

- SE Minnesota

Jeff,

If the off cut is held so it can't move, it won't drift back into the blade. How about a couple of featherboards--one on top and one on the side opposite the fence? If they were set up right, they might actually be able to pull the off cut away from the blade, too.

Make sure the sled has no lateral sloppiness in the miter gauge slot. If there is some and you push the sled through againsat the right side of the slot but pull back on the left side, the off cut will shiift toward the blade.

If the off cut is held so it can't move, it won't drift back into the blade. How about a couple of featherboards--one on top and one on the side opposite the fence? If they were set up right, they might actually be able to pull the off cut away from the blade, too.

Make sure the sled has no lateral sloppiness in the miter gauge slot. If there is some and you push the sled through againsat the right side of the slot but pull back on the left side, the off cut will shiift toward the blade.

Alan Schwabacher

Member

- Messages

- 103

- Location

- Shorewood, WI

If you made it a double runner sled, and put those hold down clamps on the parts of your stock on both sides of the cut, that would control both pieces and prevent throwing any but the very shortest of offcuts.

Jim O'Dell

Member

- Messages

- 2,783

- Location

- Between Aledo and Fort Worth, TX

Jeff, my Jointech Smart Miter has the right hand cut off sled specifically for keeping the cut offs from launching. You pull the right hand side sliding platform back so you can clear the part without being close to the blade. In all the cuts I've made with it over the years, a cut off has never been caught by the blade. Very rarely has one rattled against it, but never launched. It keeps the cut off from dropping and therefore bouncing. I didn't look at the videos here, http://www.jointech.com/smart_miter.htm to verify, but IIRC, they show the process and maybe explain some of the reasoning. I don't have Real loaded into the computer yet, and Win media player won't play them. Might be worth a look-see. I've always felt very safe with the cut off sled next to the blade. Jim.

Jeff Horton

Member

- Messages

- 4,272

- Location

- The Heart of Dixie

Finally got back on this and now I am happy with it. I would like to either dado the blocks into the base or make one out of a more substantial piece of wood. Otherwise I am pretty happy with this one.

The handles were just something I had laying around that I made and never used.

The handles were just something I had laying around that I made and never used.

glenn bradley

Member

- Messages

- 11,559

- Location

- SoCal

A sweet sled. Great evolution of a jig.

- Messages

- 36,134

- Location

- ABQ NM

Looks good, Jeff. So if you're cutting scarf joints, does than mean another kayak is in the mill?

Jeff Horton

Member

- Messages

- 4,272

- Location

- The Heart of Dixie

Looks good, Jeff. So if you're cutting scarf joints, does than mean another kayak is in the mill?

Actually I just finished building a new one and repairing another. I didn't post anything on either. Figured people had seen enough.

I am still working on the design for a small canoe. Just having trouble getting it where I am happy with it. But I am ready to spend more time on the water.

Larry Edgerton

Member

- Messages

- 197

- Location

- Northern Lower Michigan/Troll

I do scarf joints a whole different way. I see way to much to go wrong using either a RAS or a tablesaw. I cut both pieces at one time with a router if they are small and a skilsaw if they are too big for a router.

What I do is rough cut the pieces, flip the one over so it is at the same angle, clamp them together, with a little dab of hot melt out by the point that will easily come off with a chisel when done. These are clamped to a piece not unlike your sled, but that is screwed to the bench. Then I position a cutoff guide over the top of them and make the cut. If it is made with a router I climb cut to avoid breaking the fine point. Keep in mind I have rough cut and am only taking off a 1/16" at the most. If they are too large for a router, over 2"s, I cut them with a skilsaw and clean them up with a shooting board arrangement or just a piece of stickit paper on a hardwood block.

This is much faster and safer than trying to cut the end of a long piece on a stationary saw, and the results are the same or better.

What I do is rough cut the pieces, flip the one over so it is at the same angle, clamp them together, with a little dab of hot melt out by the point that will easily come off with a chisel when done. These are clamped to a piece not unlike your sled, but that is screwed to the bench. Then I position a cutoff guide over the top of them and make the cut. If it is made with a router I climb cut to avoid breaking the fine point. Keep in mind I have rough cut and am only taking off a 1/16" at the most. If they are too large for a router, over 2"s, I cut them with a skilsaw and clean them up with a shooting board arrangement or just a piece of stickit paper on a hardwood block.

This is much faster and safer than trying to cut the end of a long piece on a stationary saw, and the results are the same or better.