Art Mulder

Member

- Messages

- 3,383

- Location

- London, Ontario

Hey Folks,

Yesterday we spent the day with the kids (and their cousins families...) at the Ontario Science Center in Toronto. Great place to explore with the kids.

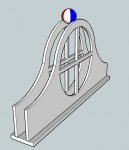

In the "Kidspark" area -- for the 8+under set -- there was this very cool build-it-yourself rollercoaster toy that I snapped a few shots of:

They play on this with hard rubber balls about 3" in diameter. My youngest (aged 5-and-a-half) played on this for almost 40 minutes straight.

So I spend the next half hour staring at it and trying to figure out how I can duplicate this.

The trick, I would think, is finding the right rubber extrusion for the top of the track. Here is a close up of the end:

My other thought was to try and scale this down to use a golf ball (or similar sized rubber ball). That would be a much smaller size toy, a little easier to fit in the basement! but again, trying to come up with the track part of the toy is the trick. I tried googling around for rubber extrusions, but didn't really find any ready-made products that seemed right. I wondered about garage door weather stripping, but that isn't the right shape either.

So I thought I'd turn to the bright folks out here on the the forum...

Ever seen a rubber extrusion like this? Any idea where I could find one -- and yes, cost is an issue.

OR, any thoughts about scaling this down to a golf-ball sized structure? Again, any ideas about a good rubber extrusion that would work?

I think a rubber track is mandatory. I've made some other small marble-works toys and wooden track is hard, and can lead to balls bouncing around. I think a rubber track would be more yielding and lead to a smoother action of the ball rolling along, more likely to stay on track.

...art

Yesterday we spent the day with the kids (and their cousins families...) at the Ontario Science Center in Toronto. Great place to explore with the kids.

In the "Kidspark" area -- for the 8+under set -- there was this very cool build-it-yourself rollercoaster toy that I snapped a few shots of:

They play on this with hard rubber balls about 3" in diameter. My youngest (aged 5-and-a-half) played on this for almost 40 minutes straight.

So I spend the next half hour staring at it and trying to figure out how I can duplicate this.

The trick, I would think, is finding the right rubber extrusion for the top of the track. Here is a close up of the end:

My other thought was to try and scale this down to use a golf ball (or similar sized rubber ball). That would be a much smaller size toy, a little easier to fit in the basement! but again, trying to come up with the track part of the toy is the trick. I tried googling around for rubber extrusions, but didn't really find any ready-made products that seemed right. I wondered about garage door weather stripping, but that isn't the right shape either.

So I thought I'd turn to the bright folks out here on the the forum...

Ever seen a rubber extrusion like this? Any idea where I could find one -- and yes, cost is an issue.

OR, any thoughts about scaling this down to a golf-ball sized structure? Again, any ideas about a good rubber extrusion that would work?

I think a rubber track is mandatory. I've made some other small marble-works toys and wooden track is hard, and can lead to balls bouncing around. I think a rubber track would be more yielding and lead to a smoother action of the ball rolling along, more likely to stay on track.

...art

Last edited: