Carol Reed

In Memoriam

- Messages

- 5,533

- Location

- Coolidge, AZ

I have been wanting to do a tutorial on a basic project. The teaching bug in me was bugging me!

The idea is to take you through the thought process as well as the construction process. So I have broken this project into several parts and will post them with their pics as I have time. It sure slows things down when you stop to take pictures!

So fill your cup and hopefully enjoy.

This Powermatic mortiser followed me home from Missouri last month. Paul Gallian had put it up on the classifieds here and I was lucky enough to grab it. I visited him and his very talented wife on my way home from North Carolina. Melissa does beautiful weaving, and you have all seen Paul’s talents elsewhere on this forum.

It is setting on one of my benches and in the way of the next installment of book shelves. It needs a home ASAP.

So, first the planning criteria. Its permanent home needs to be a roll around cabinet with at least one drawer. The wheels need to lock. It would be good to build it out of what is on hand as even the borg is a 40 mile round trip. It needs to be big enough to be stable but small enough as to not take up lots of floor real estate.

My first rule of woodworking is to get the hardware first. One has to design around hardware, so know its limitations and requirements first - and don't wait for it to become manufacturer discontinued! Get it now.

Off to the spare wheel box. I collect them as the opportunity presents itself. And I had four perfect wheels for this project. These lovelies are 5" in diameter. Better to ride over the bumps! A 3" wheel is my personal minimum. Each wheel has a brake and swivels. The overall height of this assembly is 6", so now I know how high off the floor the cabinet will be.

I really did not want bolt head protrusions in the floor of the cabinet, so I found some tee nuts, machine screws and washers.

I have just eliminated the need to build a base just for the wheels to attach to the cabinet. I like simple.

I have a box of drawer slides and I found four sets of 18" slides. Now I know the minimum depth of the cabinet.

For cabinet material I want something nice. This is a permanent home for this machine. I have some 3/4" and 1/4" left over Baltic Birch plywood from the first set of book shelves. Here is a nice piece plenty big enough.

A word on material. Crappy material to just save a couple of bucks is shortsightedness of the highest order in my world. It unnecessarily complicates the build and leads to frustration and mistakes. This is not to be woodWORKing. This is to be woodFUNning! Not to mention the final project is less than it could be and it sours me on making another. I want to be happy with the outcome. Life is too short for less. Projects are more than the final outcome. They are also a journey. So enjoy already!

Let's review. I have an overall concept, the materials, and a few necessary dimensions. I need a few more. The machine is setting on the bench. It seems to be at a good operational height. I have a very fragile back from a car wreck. I cannot work even a little bit bent over. So operational heights are very important to me.

The height of the bench is 34" off the floor; minus the 6" wheel assemblies, the cabinet box can be 28" high. I already know the depth will be at least 18" and I can't think of a reason why I would want it deeper. That means the width will be at least 18" as well. Don't want it tippy. So be it; 18" wide, 18" deep, and 28" high.

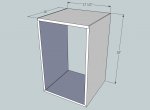

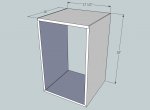

Off to the computer. It is time to boot up SketchUp.

I have an old laptop for the shop. I keep it under a dust towel until I need it. It is much handier to have it right there on the benchtop as I draw. I can go measure things right at hand, without running upstairs to my office. Cardiac exercise must be tempered with arthritic knees!

Drawing in SketchUp gives me a record of what I plan to do and automatically calculates dimensions for me. I make it a point to draw in the joinery because that often determines the cut size of pieces.

The joinery will be chosen for strength, not beauty. The weight of the machine is significant and the operational motion is downward, adding to the need for a strong box. I chose a ½” deep rabbet, wide enough to accommodate the thickness of the ends.

This way the top is resting on a ½” ledge created by the rabbet. The sides then transfer the weight to the bottom with a ½” ledge resting on the bottom. The sides will be glued and screwed to the ends, and a back will be inset to add structural integrity to the entire cabinet.

I do not draw anything more than I need at the moment. Right now I need the final cut dimensions of the ends (top and bottom) and the sides. As you can see on the drawing I added the necessary dimensions, so I am ready to cut material.

A word on not drawing ahead. "Stuff" happens when building and final cut dimensions may not exactly match what is drawn. And the discrepancies usually are not critical, but often affect things further along in the project.

If I draw only as much as I need, I don't have much to change in the drawing for the next phase of drawing. The idea is to keep the drawing matching what I am building, not so much keeping the project perfect to the drawing!

More later if you want to follow along.

Part 1

Part 2

Part 2 - Update

Part 3a

Part 3b

Part 4

Part 5

Part 6

The idea is to take you through the thought process as well as the construction process. So I have broken this project into several parts and will post them with their pics as I have time. It sure slows things down when you stop to take pictures!

So fill your cup and hopefully enjoy.

This Powermatic mortiser followed me home from Missouri last month. Paul Gallian had put it up on the classifieds here and I was lucky enough to grab it. I visited him and his very talented wife on my way home from North Carolina. Melissa does beautiful weaving, and you have all seen Paul’s talents elsewhere on this forum.

It is setting on one of my benches and in the way of the next installment of book shelves. It needs a home ASAP.

So, first the planning criteria. Its permanent home needs to be a roll around cabinet with at least one drawer. The wheels need to lock. It would be good to build it out of what is on hand as even the borg is a 40 mile round trip. It needs to be big enough to be stable but small enough as to not take up lots of floor real estate.

My first rule of woodworking is to get the hardware first. One has to design around hardware, so know its limitations and requirements first - and don't wait for it to become manufacturer discontinued! Get it now.

Off to the spare wheel box. I collect them as the opportunity presents itself. And I had four perfect wheels for this project. These lovelies are 5" in diameter. Better to ride over the bumps! A 3" wheel is my personal minimum. Each wheel has a brake and swivels. The overall height of this assembly is 6", so now I know how high off the floor the cabinet will be.

I really did not want bolt head protrusions in the floor of the cabinet, so I found some tee nuts, machine screws and washers.

I have just eliminated the need to build a base just for the wheels to attach to the cabinet. I like simple.

I have a box of drawer slides and I found four sets of 18" slides. Now I know the minimum depth of the cabinet.

For cabinet material I want something nice. This is a permanent home for this machine. I have some 3/4" and 1/4" left over Baltic Birch plywood from the first set of book shelves. Here is a nice piece plenty big enough.

A word on material. Crappy material to just save a couple of bucks is shortsightedness of the highest order in my world. It unnecessarily complicates the build and leads to frustration and mistakes. This is not to be woodWORKing. This is to be woodFUNning! Not to mention the final project is less than it could be and it sours me on making another. I want to be happy with the outcome. Life is too short for less. Projects are more than the final outcome. They are also a journey. So enjoy already!

Let's review. I have an overall concept, the materials, and a few necessary dimensions. I need a few more. The machine is setting on the bench. It seems to be at a good operational height. I have a very fragile back from a car wreck. I cannot work even a little bit bent over. So operational heights are very important to me.

The height of the bench is 34" off the floor; minus the 6" wheel assemblies, the cabinet box can be 28" high. I already know the depth will be at least 18" and I can't think of a reason why I would want it deeper. That means the width will be at least 18" as well. Don't want it tippy. So be it; 18" wide, 18" deep, and 28" high.

Off to the computer. It is time to boot up SketchUp.

I have an old laptop for the shop. I keep it under a dust towel until I need it. It is much handier to have it right there on the benchtop as I draw. I can go measure things right at hand, without running upstairs to my office. Cardiac exercise must be tempered with arthritic knees!

Drawing in SketchUp gives me a record of what I plan to do and automatically calculates dimensions for me. I make it a point to draw in the joinery because that often determines the cut size of pieces.

The joinery will be chosen for strength, not beauty. The weight of the machine is significant and the operational motion is downward, adding to the need for a strong box. I chose a ½” deep rabbet, wide enough to accommodate the thickness of the ends.

This way the top is resting on a ½” ledge created by the rabbet. The sides then transfer the weight to the bottom with a ½” ledge resting on the bottom. The sides will be glued and screwed to the ends, and a back will be inset to add structural integrity to the entire cabinet.

I do not draw anything more than I need at the moment. Right now I need the final cut dimensions of the ends (top and bottom) and the sides. As you can see on the drawing I added the necessary dimensions, so I am ready to cut material.

A word on not drawing ahead. "Stuff" happens when building and final cut dimensions may not exactly match what is drawn. And the discrepancies usually are not critical, but often affect things further along in the project.

If I draw only as much as I need, I don't have much to change in the drawing for the next phase of drawing. The idea is to keep the drawing matching what I am building, not so much keeping the project perfect to the drawing!

More later if you want to follow along.

Part 1

Part 2

Part 2 - Update

Part 3a

Part 3b

Part 4

Part 5

Part 6

Last edited by a moderator: