Matt Guyrd

Member

- Messages

- 29

- Location

- Northern Virginia

The Xmas cutting boards were a big hit this past season. I have since made a couple more by request.

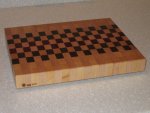

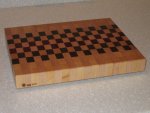

This board is maple and walnut, approx. 9"x12"x1.5".

I hap-hazardly attempted to make my mark on the boards, but have quickly realized I need to find an alternative that looks a bit more professional.

I also provide a small bottle of mineral oil, a foam applicator, and care and maintenance instructions with each board. I'm still waiting for the first knucklehead to call me saying their board fell apart after placing it in the dishwasher!

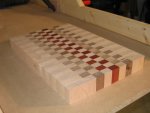

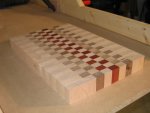

This next board is made of maple, walnut, and bloodwood.

Before glue-up.

In clamps.

After glue-up.

In most cases, the recipient preferred the rubber feet on the bottom versus two cutting surfaces. I personally like the feet as it gives the board a nice shadow line and it doesn't slide on counter tops.

Thanks for looking...comments and criticism welcomed!

Matt

This board is maple and walnut, approx. 9"x12"x1.5".

I hap-hazardly attempted to make my mark on the boards, but have quickly realized I need to find an alternative that looks a bit more professional.

I also provide a small bottle of mineral oil, a foam applicator, and care and maintenance instructions with each board. I'm still waiting for the first knucklehead to call me saying their board fell apart after placing it in the dishwasher!

This next board is made of maple, walnut, and bloodwood.

Before glue-up.

In clamps.

After glue-up.

In most cases, the recipient preferred the rubber feet on the bottom versus two cutting surfaces. I personally like the feet as it gives the board a nice shadow line and it doesn't slide on counter tops.

Thanks for looking...comments and criticism welcomed!

Matt

In particular was the alignment of rows. Also, keeping the four sides square and top/bottom flat took a little playing with too.

In particular was the alignment of rows. Also, keeping the four sides square and top/bottom flat took a little playing with too.