- Messages

- 16,585

- Location

- Reno NV

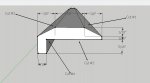

So I need to make some carpet reducer molding. Couldn't find any I liked locally, and decided I wanted the molding to match our cabinets, and since I've got a ton of maple already, I'm going to make some maple carpet reducers.

This will cover the edges of the laminate and the new carpet we are getting next week will butt up against it.

I'm thinking the order of cuts should be trimming the two top angles first, then the long cut under the modling, then the short cut to trim off the waste piece.

I've got plenty of feather boards and will make sure the workpiece is contained and controlled for each cut.

Just wanted to see if anybody had any comments on the order of the cuts.

Thanks!

This will cover the edges of the laminate and the new carpet we are getting next week will butt up against it.

I'm thinking the order of cuts should be trimming the two top angles first, then the long cut under the modling, then the short cut to trim off the waste piece.

I've got plenty of feather boards and will make sure the workpiece is contained and controlled for each cut.

Just wanted to see if anybody had any comments on the order of the cuts.

Thanks!