You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Removing Saw Guard-What do you think?

- Thread starter Allen Bookout

- Start date

Per Swenson

Member

- Messages

- 86

Concentration can be disrupted in a brief .000000001 second, at my age tend to talk too myself........it is when I answer myself that concentration is disrupted.

Whaddaya mean at your age?

I thought everybody had a conversant imaginary friend for Life.

Per

Bob Spare

Member

- Messages

- 480

Whaddaya mean at your age?

I thought everybody had a conversant imaginary friend for Life.

Per

You are right ....seen your friend didnt talk to her....but talk to mine and she is prettier than yours...

Which proves a point that everybody on this thread

consentration has been broken, USE SAFTEY EQUIPMENT for wood or otherwise

=======================

Google search: Table saw accidents here is what came up........

1,340,000 for Table saw accidents.

Enough said

=======================

Last edited:

Bill Lantry

Member

- Messages

- 2,663

- Location

- Inside the Beltway

Well, folks, I'm a little shocked. But then, I am the very definition of a complete idiot, and need everything on my side to avoid doing something stupid, and even then...

The guard on my 3650 has saved my you know what several times. It's the repetitive things that tend to get me. If I'm making the same cut 20 times, you can be certain I'll do something stupid on #17...

What worries me most is that people who don't know what they're doing read these posts to learn. I know I did. When my silly little craftsman benchtop sucked my pushstick into the blade, and nearly my hand with it, I got my 3650. Never made another cut with that little thing, it scared me so bad. Now I bless that blade gaurd almost with every cut I make.

I think people who are new to tablesaws should just google "table saw accident". There are a bunch of databases out there. They will instill a healthy fear... and they'll persuade you to use whatever you can, no matter what the more experienced people do.

In another life, I used to go skiing. I saw cool people jumping, flying over moguls, doing twists in midair. I thought "how hard can it be?" and went down a black slope. Darn near killed myself, and went happily back to the blue slopes, learning a big lesson about myself, and what's right for me. Like the poet says "a sadder and a wiser man, he woke the morrow morn." But at least I didn't have to break a leg to learn it. And I can still count to ten, in spite of all my stupidity...

The guard on my 3650 has saved my you know what several times. It's the repetitive things that tend to get me. If I'm making the same cut 20 times, you can be certain I'll do something stupid on #17...

What worries me most is that people who don't know what they're doing read these posts to learn. I know I did. When my silly little craftsman benchtop sucked my pushstick into the blade, and nearly my hand with it, I got my 3650. Never made another cut with that little thing, it scared me so bad. Now I bless that blade gaurd almost with every cut I make.

I think people who are new to tablesaws should just google "table saw accident". There are a bunch of databases out there. They will instill a healthy fear... and they'll persuade you to use whatever you can, no matter what the more experienced people do.

In another life, I used to go skiing. I saw cool people jumping, flying over moguls, doing twists in midair. I thought "how hard can it be?" and went down a black slope. Darn near killed myself, and went happily back to the blue slopes, learning a big lesson about myself, and what's right for me. Like the poet says "a sadder and a wiser man, he woke the morrow morn." But at least I didn't have to break a leg to learn it. And I can still count to ten, in spite of all my stupidity...

Last edited:

Tim Armstrong

Member

- Messages

- 69

Just one more vote for keeping the guard. For me, a guard and a splitter (with anti-kickback) are must haves. That said, I don't really like having the guard (I have the Delta overarm guard system on my Delta hybrid saw) because it gets in the way on some cuts or some jigs but if I ever get really sick of it, I'll replace it with a guard system of a different design. So, inconvenient? Yes. But not nearly as inconvenient as some missing fingers.

I was invited to an interesting event last year where the Power Tool Institute (or something like that) brought a bunch of woodworkers/contractors into a hotel conference hall where they had different guards set up on some table saws and they asked us all to talk about them, use them, set them up, etc. It was a product study of some sorts and all the guards were prototypes. I forget the exact stats but many more people don't use guards than do use them - but the industry knows it's a major problem. So, I spent an afternoon there and got to try out some guards that may eventually become products and my key takeaways were: #1 - use a guard, #2 - most of the guards on the market now stink, #3 - the power tool industry realizes that this is a long overdue area for research and investment so hopefully, we'll see some better stuff in the years to come. It was an interesting afternoon and they thanked me with a free Bosch Colt router for my time! Well worth a couple hours!

Well worth a couple hours!

I was invited to an interesting event last year where the Power Tool Institute (or something like that) brought a bunch of woodworkers/contractors into a hotel conference hall where they had different guards set up on some table saws and they asked us all to talk about them, use them, set them up, etc. It was a product study of some sorts and all the guards were prototypes. I forget the exact stats but many more people don't use guards than do use them - but the industry knows it's a major problem. So, I spent an afternoon there and got to try out some guards that may eventually become products and my key takeaways were: #1 - use a guard, #2 - most of the guards on the market now stink, #3 - the power tool industry realizes that this is a long overdue area for research and investment so hopefully, we'll see some better stuff in the years to come. It was an interesting afternoon and they thanked me with a free Bosch Colt router for my time!

Last edited:

Allen Bookout

Member

- Messages

- 902

- Location

- Punta Gorda, Florida

Allen

By the way, I get a lot of top side dust, especially when trimming a board.

When I said that I do not get much dust on top that is not true when trimming the edge of a board but my dust collector setup would not pick it up anyway.

A lot of good information comming in.

Thanks!

Jesse Cloud

Member

- Messages

- 688

OK, I'll take my turn on the soapbox... As for the guard, all the ones I have tried were worse than useless, but I have an open mind and if one came on the market that really worked (provided safety and sucked dust) I would jump on it.

Now splitters are another matter altogether. I always use a splitter. No matter how thoroughly you think thru or practice a cut, sometimes wood can be ornery and just decide to close up on you once it passes the blade. Use that splitter

I think the important thing is to find safety practices that you will actually use. That safety device hanging on the wall doesn't do you a bit of good!

I'm also a big fan of the grrripper. When something just doesn't feel right on the table saw, I head for the bandsaw or the festool without a second thought!

There's room for respectful disagreement on this topic.

Now splitters are another matter altogether. I always use a splitter. No matter how thoroughly you think thru or practice a cut, sometimes wood can be ornery and just decide to close up on you once it passes the blade. Use that splitter

I think the important thing is to find safety practices that you will actually use. That safety device hanging on the wall doesn't do you a bit of good!

I'm also a big fan of the grrripper. When something just doesn't feel right on the table saw, I head for the bandsaw or the festool without a second thought!

There's room for respectful disagreement on this topic.

Cecil Arnold

Member

- Messages

- 363

- Location

- Houston, TX

OK, I'll take my turn on the soapbox... As for the guard, all the ones I have tried were worse than useless, but I have an open mind and if one came on the market that really worked (provided safety and sucked dust) I would jump on it.

Now splitters are another matter altogether. I always use a splitter. No matter how thoroughly you think thru or practice a cut, sometimes wood can be ornery and just decide to close up on you once it passes the blade. Use that splitter

I think the important thing is to find safety practices that you will actually use. That safety device hanging on the wall doesn't do you a bit of good!

I'm also a big fan of the grrripper. When something just doesn't feel right on the table saw, I head for the bandsaw or the festool without a second thought!

There's room for respectful disagreement on this topic.

I couldn't agree more with Jesse's comments. Until the industry comes up with something that is, IMHO, more useful than dangerous, I'll do without.

- Messages

- 6,941

- Location

- Austintown, Ohio

[size=+1]It doesn't have dust collection, but I really like my Delta Uniguard, and I use it - along with the Biesemeyer splitter - virtually all the time.

BTW, with a zero clearance insert, I really don't find above-the-table dust to be that much of a problem. There's a little bit, but not all that much.

On another note - I use push sticks for nearly every cut, but the Grripper still scares me a bit. I'm just not that comfortable using it on the table saw. I'd rather do those 'questionable' cuts on the bandsaw or (GASP!!) by hand.[/size]

BTW, with a zero clearance insert, I really don't find above-the-table dust to be that much of a problem. There's a little bit, but not all that much.

On another note - I use push sticks for nearly every cut, but the Grripper still scares me a bit. I'm just not that comfortable using it on the table saw. I'd rather do those 'questionable' cuts on the bandsaw or (GASP!!) by hand.[/size]

Jesse Cloud

Member

- Messages

- 688

[size=+1] I'd rather do those 'questionable' cuts on the bandsaw or (GASP!!) by hand.[/size]

Gasp!! Cut wood by hand

You got it Jim. I forgot to mention that safety device. Especially for rough cutting thick stock - its my favorite

Frank Pellow

Member

- Messages

- 2,332

- Location

- Toronto, Ontario, CANADA

A recent poll (http://www.canadianwoodworking.com/forum/showthread.php?t=14889) on the Canadian Woodworking forum indicates that only 37% of folks who responded use a guard on their table saws (65 d0, 113 do not).

On the other hand, 62% of those responding to another pool (http://www.canadianwoodworking.com/forum/showthread.php?t=14889) do muse a splitter or riving knife.

On the other hand, 62% of those responding to another pool (http://www.canadianwoodworking.com/forum/showthread.php?t=14889) do muse a splitter or riving knife.

Don Bergren

Member

- Messages

- 15

- Location

- Midcoast, Maine

In high school shop they really emphasized the concept of safety being an important part of tool usage. We watched the gore films, and were told repeatably why the stationary power tools had guards. I have to admit that those lessons from high school have remained with me. Thanks Mr. Bailey, Mr. Hartford, Mr. Newcomb, and Mr. Darby; your lessons have stayed with me all these years.

I always use a guard if possible on my table saw. The guard and splitter are things I sometimes view has a being a bit of a hassel, but at the same time I see them as having value to me. For me I've always felt that they work with me a lot more than they work against me. I'm extremely careful when using my tools, but I still view the guards as giving me an extra edge if something should go horribly wrong.

To be honest, I don't use the table saw too much these days. I now do most of the things with my EZ Smart that I used to do with my table saw. But for those occasional cuts that require the table saw, I use the blade guard and splitter.

I always use a guard if possible on my table saw. The guard and splitter are things I sometimes view has a being a bit of a hassel, but at the same time I see them as having value to me. For me I've always felt that they work with me a lot more than they work against me. I'm extremely careful when using my tools, but I still view the guards as giving me an extra edge if something should go horribly wrong.

To be honest, I don't use the table saw too much these days. I now do most of the things with my EZ Smart that I used to do with my table saw. But for those occasional cuts that require the table saw, I use the blade guard and splitter.

Doug Shepard

In Memorium

- Messages

- 772

- Location

- Waterford, MI

What's a guard?

Allen Bookout

Member

- Messages

- 902

- Location

- Punta Gorda, Florida

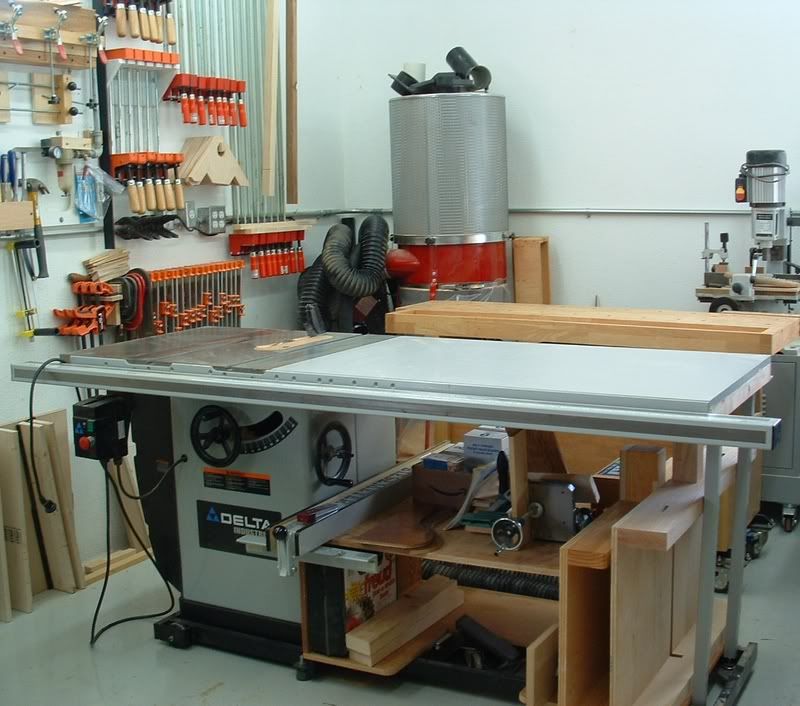

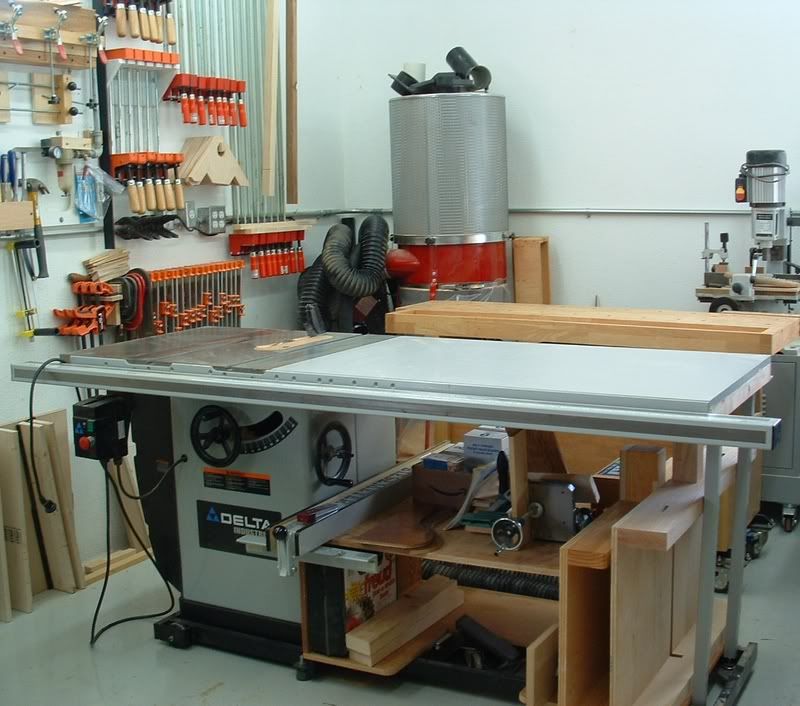

I finally made my decision, good or bad, and it is shown below.

I finally feel free at last. No more horizontal or vertical braces to get in the way. I felt that the vertical brace at the end of the table could be a safety issue if you got careless. I did keep my "system" just in case I changed my mind but right now I do not see that happening after seeing everything opened up. Now to just try to keep all of my fingers and hands.

I did use a 1969 Craftsman radial arm saw for over thirty years and after getting whacked around with that thing a few times I did learn a thing or two about caution. Maybe that experience will leave me in good stead.

If everything does not seem right when I am ready for a cut I will change tactics. I have a bandsaw, Sliding compound miter saw and the EZ system should I need to substitute or use one of them in the first place. Did I say "EZ" on a woodworking forum? If anyone says that I did I will flatly deny it. Doesn't take me long to catch on.

Thanks to all of you for your input!!!!!

Allen

I finally feel free at last. No more horizontal or vertical braces to get in the way. I felt that the vertical brace at the end of the table could be a safety issue if you got careless. I did keep my "system" just in case I changed my mind but right now I do not see that happening after seeing everything opened up. Now to just try to keep all of my fingers and hands.

I did use a 1969 Craftsman radial arm saw for over thirty years and after getting whacked around with that thing a few times I did learn a thing or two about caution. Maybe that experience will leave me in good stead.

If everything does not seem right when I am ready for a cut I will change tactics. I have a bandsaw, Sliding compound miter saw and the EZ system should I need to substitute or use one of them in the first place. Did I say "EZ" on a woodworking forum? If anyone says that I did I will flatly deny it. Doesn't take me long to catch on.

Thanks to all of you for your input!!!!!

Allen

Last edited:

Allen Bookout

Member

- Messages

- 902

- Location

- Punta Gorda, Florida

What's a guard?

That's a good one Doug!

S

Steve Clardy

Guest

Allen. Anyone ever tell you your shop's too clean?

All I use is a ZCI and Splitter

All I use is a ZCI and Splitter

Allen Bookout

Member

- Messages

- 902

- Location

- Punta Gorda, Florida

Allen. Anyone ever tell you your shop's too clean?

All I use is a ZCI and Splitter

That is what I like about my aircompressor, I can blow all of the stuff to another corner when I get ready to take a picture.

Thanks for the info.

Geoff Barry

Member

- Messages

- 20

Interesting. I started woodworking a few years ago, when I was approaching 40. You couldn't pay me enough money to use my saw without the guard for through cuts I have a bt3100, and find the guard fairly easy to use. A friend of mine bought a used unisaw recently, and we just set up his bessimeier overarm guard, which also seemed pretty easy to use. I only do this as a hobby, so I'm willing to put up with a little "annoyance" for the sake of safety. After all, as with so many things, if you pay attention, you can almost always do things safely. Safety devices, though, come into their own in the event that 1) you stop paying attention for some reason, or 2) the inverse of that "almost always" suddenly appears.

Everything has limits - there are few absolutes in life. While I'd sure like a sawstop, I imagine I'm far more likely to move up to a used unisaw or grizzly than I am a sawstop or a slider. I can conceive of spending $1200 on a saw, but not $4000 (barring a suden change in my fortunes for the better ), no matter how much I'd like one. But a guard seems like a fairly low-cost safety measure. Once again, though, I'm just a casual hobbyist - any annoyance or delay caused by the guard is fleeting. For a production sort of setup, a lot of little annoyances may add up to one big annoyance.

), no matter how much I'd like one. But a guard seems like a fairly low-cost safety measure. Once again, though, I'm just a casual hobbyist - any annoyance or delay caused by the guard is fleeting. For a production sort of setup, a lot of little annoyances may add up to one big annoyance.

Everything has limits - there are few absolutes in life. While I'd sure like a sawstop, I imagine I'm far more likely to move up to a used unisaw or grizzly than I am a sawstop or a slider. I can conceive of spending $1200 on a saw, but not $4000 (barring a suden change in my fortunes for the better

Dan Forman

Member

- Messages

- 60

- Location

- Spokane, WA

I never used a guard until I made this one recently, more for the dust collection than than accident protection.

I am finding it very cumbersome, and considering a Shark Guard instead. There have been more tense moments in the short time that the guard has been in place than in times prior. I have a basement shop, so DC is important to me. The problem for me is not the relatively heavy stuff that ends up on the table, but the fine stuff that is launched into the air.

For pushsticks, I always use the type that project well forward and above the workpiece, the fishtail type that push from the back like the orange one on the right of the picture scare me, that one serves a different purpose.

Dan

I am finding it very cumbersome, and considering a Shark Guard instead. There have been more tense moments in the short time that the guard has been in place than in times prior. I have a basement shop, so DC is important to me. The problem for me is not the relatively heavy stuff that ends up on the table, but the fine stuff that is launched into the air.

For pushsticks, I always use the type that project well forward and above the workpiece, the fishtail type that push from the back like the orange one on the right of the picture scare me, that one serves a different purpose.

Dan

Stuart Ablett

Member

- Messages

- 15,917

- Location

- Tokyo Japan

If you have a good guard on your saw, I'd say it is a good thing to use it.

My DeWalt BT saw came with a really poorly designed guard, it was seriously dangerous, it was an law suit waiting to happen, it flopped around and it would cause pieces of wood being pushed through the saw to twist or bind up. I took it off, but felt VERY uncomfortable using it, so I redesigned it as a splitter with anti-kickback pawls...........

The thing is, I find I use the TS very little now, that I have the Festool system.

I will use the TS with my Dado stack, that is one place where the TS still has the edge.

If your tool has a good, well functioning guard, and you choose to remove it, that is your choice, but I would just question why you are doing so, as it makes no sense to me.

If you tool comes with a guard that is poorly designed and causes safety issues, then I can see why it would be removed, but at least try to mitigate the risk in some additional way.

Stay safe!

My DeWalt BT saw came with a really poorly designed guard, it was seriously dangerous, it was an law suit waiting to happen, it flopped around and it would cause pieces of wood being pushed through the saw to twist or bind up. I took it off, but felt VERY uncomfortable using it, so I redesigned it as a splitter with anti-kickback pawls...........

The thing is, I find I use the TS very little now, that I have the Festool system.

I will use the TS with my Dado stack, that is one place where the TS still has the edge.

If your tool has a good, well functioning guard, and you choose to remove it, that is your choice, but I would just question why you are doing so, as it makes no sense to me.

If you tool comes with a guard that is poorly designed and causes safety issues, then I can see why it would be removed, but at least try to mitigate the risk in some additional way.

Stay safe!