- Messages

- 36,123

- Location

- ABQ NM

Some weekends it just doesn't pay to go out into the shop.

After waiting a week to get the replacement belt for my Sears lathe, it showed up Saturday, so the weekend started out on a positive note.

Then it went downhill from there. I installed the new belt, buttoned up the headstock, and mounted a roughly 10" x 5" chunk of red eucalyptus. As I was roughing it out, I thought I could hear the new (toothed) drive belt slipping a little bit. I stopped, opened things back up again, and made sure I had as much slack adjusted out of the belt as possible. I went back to turning, and for a little while the adjustment seemed to have helped, but before long it was slipping again. In the meantime, I got the red eucalyptus hollow form roughed out, plus a nice spalted hackberry HF.

Next, I decided to try out my newly-finished Longworth chuck to revise the bottom of one of my earlier bowls. One quick catch later, the bowl was launched, minus a big chunk from the rim. OK, says I, it'll just be a shorter bowl. I managed to reshape the bottom and cut a tenon, then re-turned the inside of the bowl. As I'm sanding the bowl, I'm hearing more and more belt slipping. I opened up the headstock again and tried more adjustment. No real improvement, and I quit for now on the bowl, because I didn't feel like sanding out the few deep tearouts inside the bowl, and the more I tried to clean them up with sharp chisels, the worse they got.

Monday comes along. I had the day off, so I decided to limp the lathe along enough to finish turning a 9" walnut bowl that's been drying. Despite a few catches and more tearout than I'd like to admit, I got it sanded nice and smooth, and flipped it around to cut the tenon off. (All along the drive belt was getting worse and worse.) Dummy me, I ended up making my first funnel. It's made of beautifully figured walnut, but it's a funnel nonetheless. Then when it launched from the Longworth chuck as I tried to trim up the hole in the bottom, it whanged me in the forehead as a parting shot. Fortunately, it was spinning relatively slowly, so no blood, no foul. You don't have to beat me on the head more than once or twice for me to take a hint. I decided I was done for the day.

It's made of beautifully figured walnut, but it's a funnel nonetheless. Then when it launched from the Longworth chuck as I tried to trim up the hole in the bottom, it whanged me in the forehead as a parting shot. Fortunately, it was spinning relatively slowly, so no blood, no foul. You don't have to beat me on the head more than once or twice for me to take a hint. I decided I was done for the day.

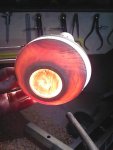

Bad words were said. Repeatedly. All weekend. Culminating in this:

I'm seriously trying to figure out the quickest way to pay for a better lathe. (And also how to convince LOML that I should spend that much money.) I'm tired of spending more time messing with belts than turning. In the meantime I'll try to get in touch with the guy at Palmgren that Bernie recommended last week and see if he has any suggestions for how to keep my lathe from eating belts. I bought the lathe used, so I have no warranty, but hopefully he can steer me in the right direction.

I'm tired of spending more time messing with belts than turning. In the meantime I'll try to get in touch with the guy at Palmgren that Bernie recommended last week and see if he has any suggestions for how to keep my lathe from eating belts. I bought the lathe used, so I have no warranty, but hopefully he can steer me in the right direction.

After waiting a week to get the replacement belt for my Sears lathe, it showed up Saturday, so the weekend started out on a positive note.

Then it went downhill from there. I installed the new belt, buttoned up the headstock, and mounted a roughly 10" x 5" chunk of red eucalyptus. As I was roughing it out, I thought I could hear the new (toothed) drive belt slipping a little bit. I stopped, opened things back up again, and made sure I had as much slack adjusted out of the belt as possible. I went back to turning, and for a little while the adjustment seemed to have helped, but before long it was slipping again. In the meantime, I got the red eucalyptus hollow form roughed out, plus a nice spalted hackberry HF.

Next, I decided to try out my newly-finished Longworth chuck to revise the bottom of one of my earlier bowls. One quick catch later, the bowl was launched, minus a big chunk from the rim. OK, says I, it'll just be a shorter bowl. I managed to reshape the bottom and cut a tenon, then re-turned the inside of the bowl. As I'm sanding the bowl, I'm hearing more and more belt slipping. I opened up the headstock again and tried more adjustment. No real improvement, and I quit for now on the bowl, because I didn't feel like sanding out the few deep tearouts inside the bowl, and the more I tried to clean them up with sharp chisels, the worse they got.

Monday comes along. I had the day off, so I decided to limp the lathe along enough to finish turning a 9" walnut bowl that's been drying. Despite a few catches and more tearout than I'd like to admit, I got it sanded nice and smooth, and flipped it around to cut the tenon off. (All along the drive belt was getting worse and worse.) Dummy me, I ended up making my first funnel.

It's made of beautifully figured walnut, but it's a funnel nonetheless. Then when it launched from the Longworth chuck as I tried to trim up the hole in the bottom, it whanged me in the forehead as a parting shot. Fortunately, it was spinning relatively slowly, so no blood, no foul. You don't have to beat me on the head more than once or twice for me to take a hint. I decided I was done for the day.

It's made of beautifully figured walnut, but it's a funnel nonetheless. Then when it launched from the Longworth chuck as I tried to trim up the hole in the bottom, it whanged me in the forehead as a parting shot. Fortunately, it was spinning relatively slowly, so no blood, no foul. You don't have to beat me on the head more than once or twice for me to take a hint. I decided I was done for the day.Bad words were said. Repeatedly. All weekend. Culminating in this:

I'm seriously trying to figure out the quickest way to pay for a better lathe. (And also how to convince LOML that I should spend that much money.)