glenn bradley

Member

- Messages

- 11,544

- Location

- SoCal

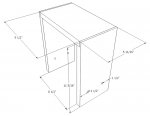

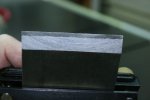

I think a few of us on here have the Worksharp. I really like this thing as I have no freehand sharpening ability to speak of. I started to restore an old plane that, of course, had an iron wider than 2". I had seen variations on this idea and being lazy, rendered it down to as simple as I could get it and have it remain functional  .

.

I adapted it to the storage box/stand that I built here. The jig bolt-knobs thread into t-nuts on the inside of the case. The holes in the table sides are over-sized to allow me to adjust for level and different abrasive thicknesses. Once the glue dries in the rabbets overnight I'll knock the sharp edges off and throw a coat of shellac on it to match the base.

I adapted it to the storage box/stand that I built here. The jig bolt-knobs thread into t-nuts on the inside of the case. The holes in the table sides are over-sized to allow me to adjust for level and different abrasive thicknesses. Once the glue dries in the rabbets overnight I'll knock the sharp edges off and throw a coat of shellac on it to match the base.

Attachments

Last edited: