mike marvel

Member

- Messages

- 267

- Location

- So. Florida

I found out that a post can't be made to "Tips", so I posted it here.

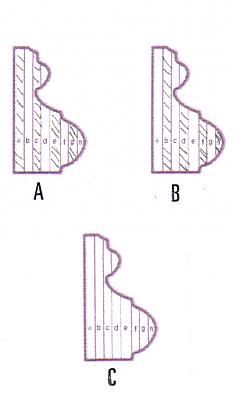

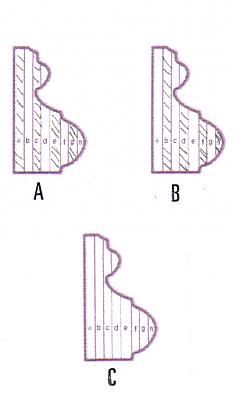

This is a procedure to make curved moulding, that is of any profile. If what you want is larger or longer than the solid stock you have, or it's too much to make it out of solid stock, this might work for you. I came up with this method many years ago out of necessity, with excellent results. The idea with this is you will be needing two (2) lengths of identical moulding "A" and "B", to make curved piece "C". Keep in mind this is a lamination method and the final moulding will have varied grain due to it being laminated from two different pieces of wood.

As you see in the drawings, "C" is cut to be glued up and installed along its left side. You can start with buying two identical pieces of moulding or make them. The drawings for this explanation are segmented into 1/8" sections, to facilitate the use of an 1/8" kerf cut. Most woods will bend well in 1/8" thickness. Each segment of "A" and "B" represent a "save" or "saw kerf".

The cross hatched segments represent a "saw kerf". So, after slicing on the TS the segments of both "A" and "B", you will save the segments "a" from "B", "b" from "A", "c" from "B", "d" from "A", etc, for the rest of the profile.

When you have the "saved" segments they will get glued up to form "C" moulding. They can be glued up and clamped all at once or a few at a time. It's imperative to align the moulding up so the profile will be consistent.

Taller curves can be created by just vertically stacking one or more profiles, provided you have made forms for the moulding to glue to. Segments that are covered by another segment can be pin nailed if necessary.

.

.

This is a procedure to make curved moulding, that is of any profile. If what you want is larger or longer than the solid stock you have, or it's too much to make it out of solid stock, this might work for you. I came up with this method many years ago out of necessity, with excellent results. The idea with this is you will be needing two (2) lengths of identical moulding "A" and "B", to make curved piece "C". Keep in mind this is a lamination method and the final moulding will have varied grain due to it being laminated from two different pieces of wood.

As you see in the drawings, "C" is cut to be glued up and installed along its left side. You can start with buying two identical pieces of moulding or make them. The drawings for this explanation are segmented into 1/8" sections, to facilitate the use of an 1/8" kerf cut. Most woods will bend well in 1/8" thickness. Each segment of "A" and "B" represent a "save" or "saw kerf".

The cross hatched segments represent a "saw kerf". So, after slicing on the TS the segments of both "A" and "B", you will save the segments "a" from "B", "b" from "A", "c" from "B", "d" from "A", etc, for the rest of the profile.

When you have the "saved" segments they will get glued up to form "C" moulding. They can be glued up and clamped all at once or a few at a time. It's imperative to align the moulding up so the profile will be consistent.

Taller curves can be created by just vertically stacking one or more profiles, provided you have made forms for the moulding to glue to. Segments that are covered by another segment can be pin nailed if necessary.

.

.