mike marvel

Member

- Messages

- 268

- Location

- So. Florida

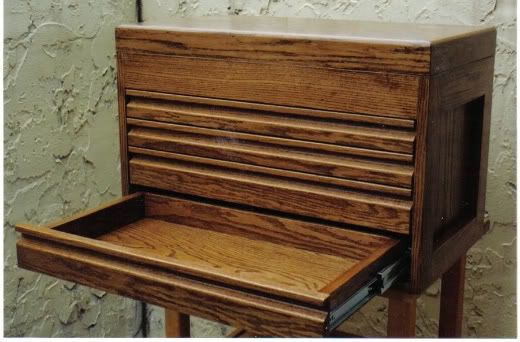

I wasn't going to post this, as it's similar to one I posted in this thread, and there wasn't much interest in it. I encourage comments both constructive and demeaning.  If you think they are a POS, say so and offer suggestions on how they can be improved.

If you think they are a POS, say so and offer suggestions on how they can be improved.

.

.

.

.

If you think they are a POS, say so and offer suggestions on how they can be improved.

If you think they are a POS, say so and offer suggestions on how they can be improved..

.

.

.