Stuart Ablett

Member

- Messages

- 15,917

- Location

- Tokyo Japan

My jointer is a used item I got off auction here in Japan, it is old, but works well, when tuned up. Recently I got the >> Veritas 50" Aluminum Straight Edge << from Lee Valley, with that I was able to set up my jointer tables as flat as I could make them. Using it I set up the knives as close as possible, but there certainly was room for improvement. I looked around at various other methods but finally decided to buy the >> OneWay Multi-Gauge << yes it is expensive, but boy is it easy to use and dead on accurate.

Here it is....

Here is how I set up the knives on my old school jointer, if you have a newer jointer, trust me, you are miles ahead of me.....

My jointer only has two knives, they are held in place by three large bolts. I loosen the bolts about 1/8 of a turn and this gives me enough play to adjust the knives.

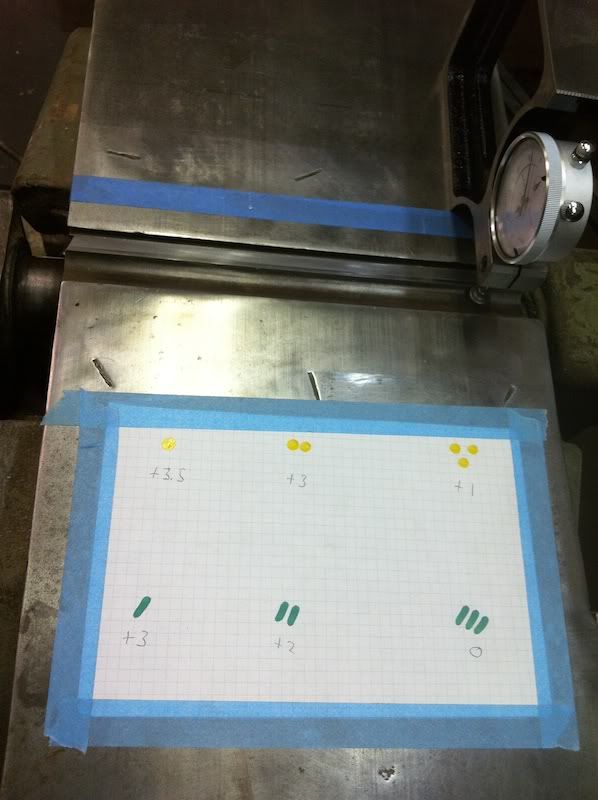

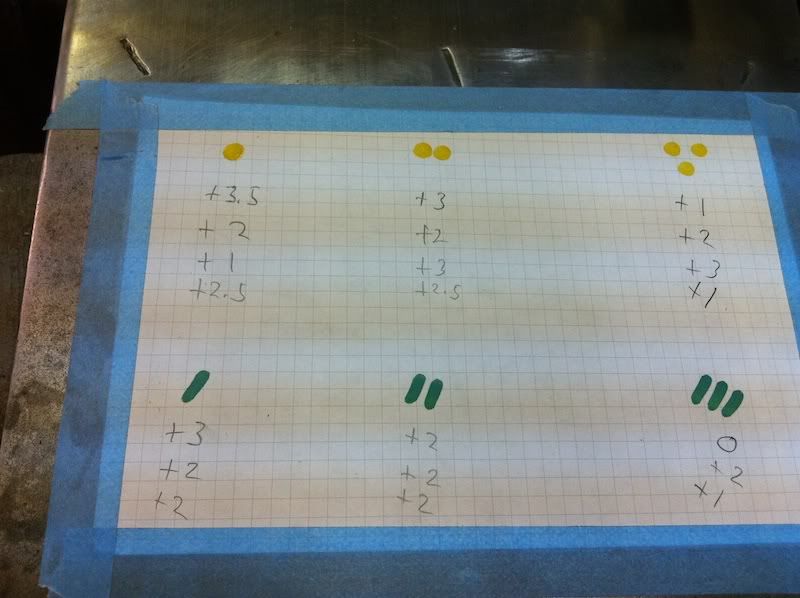

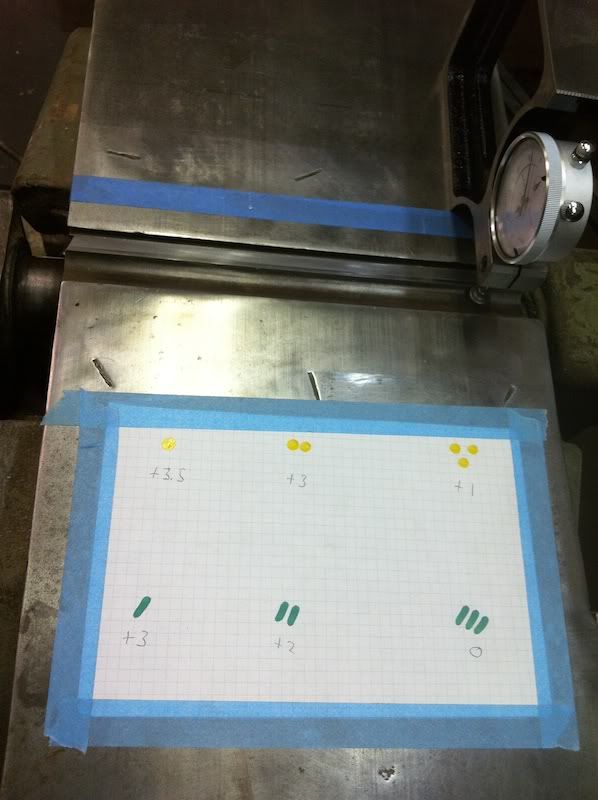

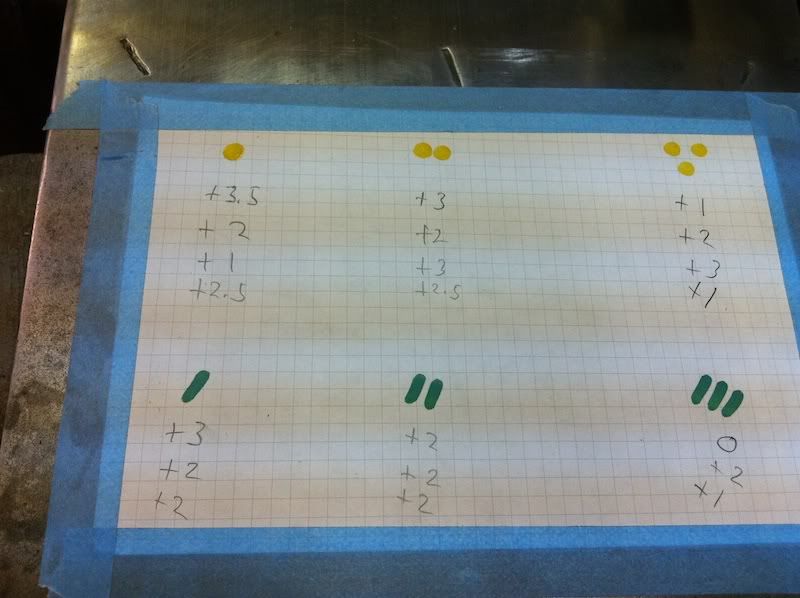

I have each bolt marked on each blade, when I remove the blades for sharpening, this also makes sure that the same bolts are used in the same holes each time. I tape on a piece of paper on the infeed table and keep track of my readings there, I also put a piece of tape on the outfeed table to make sure I am putting the Multi-Gauge in the same spot, so it reads on the Top Dead Center (TDC) of the arc of the knives.

If the blade is a bit high, I take a center punch and hit it with a hammer on the front corner of the blade, there is an indentation on the blade just for this purpose.

If the blade is too low, I rotate the head and hit the back side of the blade, again there is an indentation for the punch to register on.

Adjusting the knives with a punch and hammer, is kind of a black art, how hard you hit each time and how much you hit is tricky, I've gotten better with more practice. The Multi-Gauge really works well here, as I can check my progress, or not, easily. You can see I came out just a bit over a thousandth of an inch off from left to right, and one knife is about a thousandth of an inch higher than the other, brother, that is close enough for this guy!!

After putting the board through my planer I had a few marks, left from slight chips in the planer blade (I need to swap out for the fresh ones I have!).....

A couple of swipes with my #4 1/2 smoothing plane and this board is ready to be cut up for face frames.

So how easy is your jointer to set up compared to mine?

I have been toying with the idea of getting a spiral head for this jointer, all it costs is money........

Cheers!

Here it is....

Here is how I set up the knives on my old school jointer, if you have a newer jointer, trust me, you are miles ahead of me.....

My jointer only has two knives, they are held in place by three large bolts. I loosen the bolts about 1/8 of a turn and this gives me enough play to adjust the knives.

I have each bolt marked on each blade, when I remove the blades for sharpening, this also makes sure that the same bolts are used in the same holes each time. I tape on a piece of paper on the infeed table and keep track of my readings there, I also put a piece of tape on the outfeed table to make sure I am putting the Multi-Gauge in the same spot, so it reads on the Top Dead Center (TDC) of the arc of the knives.

If the blade is a bit high, I take a center punch and hit it with a hammer on the front corner of the blade, there is an indentation on the blade just for this purpose.

If the blade is too low, I rotate the head and hit the back side of the blade, again there is an indentation for the punch to register on.

Adjusting the knives with a punch and hammer, is kind of a black art, how hard you hit each time and how much you hit is tricky, I've gotten better with more practice. The Multi-Gauge really works well here, as I can check my progress, or not, easily. You can see I came out just a bit over a thousandth of an inch off from left to right, and one knife is about a thousandth of an inch higher than the other, brother, that is close enough for this guy!!

After putting the board through my planer I had a few marks, left from slight chips in the planer blade (I need to swap out for the fresh ones I have!).....

A couple of swipes with my #4 1/2 smoothing plane and this board is ready to be cut up for face frames.

So how easy is your jointer to set up compared to mine?

I have been toying with the idea of getting a spiral head for this jointer, all it costs is money........

Cheers!

If not the jointer, then maybe I should see if they make a spiral cut head for my planer

If not the jointer, then maybe I should see if they make a spiral cut head for my planer  I kind of doubt it, as it was not a popular planer in the US etc, but maybe Makita used the same parts in my planer as the ones that were sold in the US....

I kind of doubt it, as it was not a popular planer in the US etc, but maybe Makita used the same parts in my planer as the ones that were sold in the US....