John Hemenway

Member

- Messages

- 138

- Location

- Santa Rosa, CA

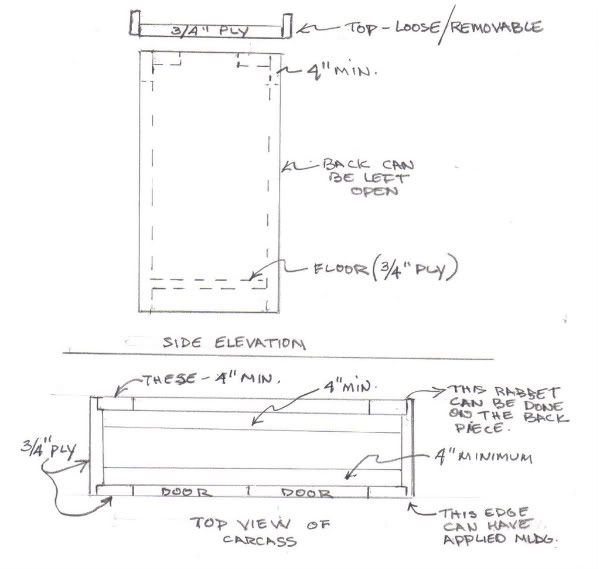

I've started the SketchUp design to build a stand for a new aquarium. The aquarium will be about 48x24x24 inches. This will be about 120 gallons. Final weight will be aprox. 1000 lbs.

Please take a look at the (hopefully) attached sketch. Do you see any structural problems?

The stand will be made out of birch ply and most likely maple for the face frame. I'm trying to create a very plain look similar to the style of an ADA stand ( www.adana.co.jp/en/products/na_tank/wood_cabinet ). The doors will be inset plain panels. The finish will be grey paint or some other opaque grey finish. Is it possible to tint poly to get an opaque finish? I've only done stain and clear coat poly or lacquer on cabinets.

Anyway that's it for now. Please feel free to comment/critique!

Please take a look at the (hopefully) attached sketch. Do you see any structural problems?

The stand will be made out of birch ply and most likely maple for the face frame. I'm trying to create a very plain look similar to the style of an ADA stand ( www.adana.co.jp/en/products/na_tank/wood_cabinet ). The doors will be inset plain panels. The finish will be grey paint or some other opaque grey finish. Is it possible to tint poly to get an opaque finish? I've only done stain and clear coat poly or lacquer on cabinets.

Anyway that's it for now. Please feel free to comment/critique!