glenn bradley

Member

- Messages

- 11,559

- Location

- SoCal

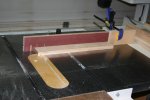

Doesn't seem like much output for the past few hours I've put in. Figure selection for those parts that will be facing the viewer ate up about a third of my time. I did get the drawer fronts selected and broken out into oversized pieces. These are some of the frame / leg parts. The legs are glued up blanks so I hope to get them into the clamps before I call it a day.

Hmmm, that went faster than I thought. I shoot 1/2" pins, left proud, into the surfaces of large areas that will be slick with glue to prevent creep during glue-up.

Some bowed cauls and a workbench combine to make a nice big clamp.

.

.

Hmmm, that went faster than I thought. I shoot 1/2" pins, left proud, into the surfaces of large areas that will be slick with glue to prevent creep during glue-up.

Some bowed cauls and a workbench combine to make a nice big clamp.

.

.

Last edited:

.

.