- Messages

- 11,632

- Location

- Constantine, MI

This is a follow up to the drill press table build thread.

The last thing I need to do to make my drill press really perform the way I need it to is replace the factory chuck. The chuck that came with the press will not accept a bit under 1/4" in diameter. Note the 5-20 MM marking.

I looked at the one suggested by Glenn, and I also found this one on Amazon. Looks like tha Amazon one has very good reviews and a great price.

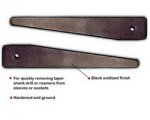

My dilemma, I've never replaced a chuck before. Is the taper on my press the same as mentioned in the Amazon ad? "1/32-1/2" VME Keyless Drill Chuck, 33 Jacobs Taper mount". My current chuck is labeled "J3". Is that a clue?

Help!

The last thing I need to do to make my drill press really perform the way I need it to is replace the factory chuck. The chuck that came with the press will not accept a bit under 1/4" in diameter. Note the 5-20 MM marking.

I looked at the one suggested by Glenn, and I also found this one on Amazon. Looks like tha Amazon one has very good reviews and a great price.

My dilemma, I've never replaced a chuck before. Is the taper on my press the same as mentioned in the Amazon ad? "1/32-1/2" VME Keyless Drill Chuck, 33 Jacobs Taper mount". My current chuck is labeled "J3". Is that a clue?

Help!