Ken Cook

Member

- Messages

- 3,798

I was not happy with the spring tension type of retainers on my TS insert.

It {the insert} had a slight tendency with any downward pressure upon the operators end, to lift/pop up & out some at the out-feed end...probably just like me>worn out , but still, a little nerve racking to say the least. So instead of trying to copy the design or even use the original retainers in the new zero clearance inserts, I decided to make things a tad more secure.

, but still, a little nerve racking to say the least. So instead of trying to copy the design or even use the original retainers in the new zero clearance inserts, I decided to make things a tad more secure.

The saw's throat opening has 4 tabs or ears if you will, that the height adjusting set-screws rest upon.

Being that there was plenty of area on each ear, I decided to tap 2 opposing corner tabs to accept 1/4-20 allen head bolts to fasten the insert directly to the TS.

Once I had those drilled & tapped, I made a templet from a piece of 1/4" plexiglass which made it very easy to locate each opening for transferring the locations.

I used one of those self-centering spring loaded bits to keep centered, and followed up with a step drill bit which allowed the 1/4" opening for the bolt threads & a 3/8" recess for the bolt head. I also drilled a finger 'pull' hole to aid in removing the insert.

Then it was simply a matter of drilling & tapping for the 1/4-20 height adjusting set screws.

end result...

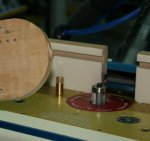

On a related note, I found out that with a 10" blade lowered all the way possible, that it was still too high to secure the insert down & raise the blade up to cut it's zero clearance opening...I looked at a few how to's on utube where the folks were lowering the insert onto a spinning blade...Uhhhmmm no thanks, I've already had the displeasure of donating finger meat to the blade Gods . I just ran the insert {bottom down} across the router table with a 1/4" straight bit set to eat 3/8", that allowed enough clearance, to, as they say, 'git 'er done'.

. I just ran the insert {bottom down} across the router table with a 1/4" straight bit set to eat 3/8", that allowed enough clearance, to, as they say, 'git 'er done'.

So tell me, was this over-kill or the wrong direction? Any suggestions will be noted towards future inserts, & appreciated!

It {the insert} had a slight tendency with any downward pressure upon the operators end, to lift/pop up & out some at the out-feed end...probably just like me>worn out

, but still, a little nerve racking to say the least. So instead of trying to copy the design or even use the original retainers in the new zero clearance inserts, I decided to make things a tad more secure.

, but still, a little nerve racking to say the least. So instead of trying to copy the design or even use the original retainers in the new zero clearance inserts, I decided to make things a tad more secure.The saw's throat opening has 4 tabs or ears if you will, that the height adjusting set-screws rest upon.

Being that there was plenty of area on each ear, I decided to tap 2 opposing corner tabs to accept 1/4-20 allen head bolts to fasten the insert directly to the TS.

Once I had those drilled & tapped, I made a templet from a piece of 1/4" plexiglass which made it very easy to locate each opening for transferring the locations.

I used one of those self-centering spring loaded bits to keep centered, and followed up with a step drill bit which allowed the 1/4" opening for the bolt threads & a 3/8" recess for the bolt head. I also drilled a finger 'pull' hole to aid in removing the insert.

Then it was simply a matter of drilling & tapping for the 1/4-20 height adjusting set screws.

end result...

On a related note, I found out that with a 10" blade lowered all the way possible, that it was still too high to secure the insert down & raise the blade up to cut it's zero clearance opening...I looked at a few how to's on utube where the folks were lowering the insert onto a spinning blade...Uhhhmmm no thanks, I've already had the displeasure of donating finger meat to the blade Gods

So tell me, was this over-kill or the wrong direction? Any suggestions will be noted towards future inserts, & appreciated!