Stuart Ablett

Member

- Messages

- 15,917

- Location

- Tokyo Japan

I love my 9" Comfort Rest, it is REALLY nice

but I often find it too large for some things, I'd love to get the 6" and the 4" but they cost a bit $53 and $49 respectively and shipping is not cheap as they are heavy, plus I'd live to have one like..... today

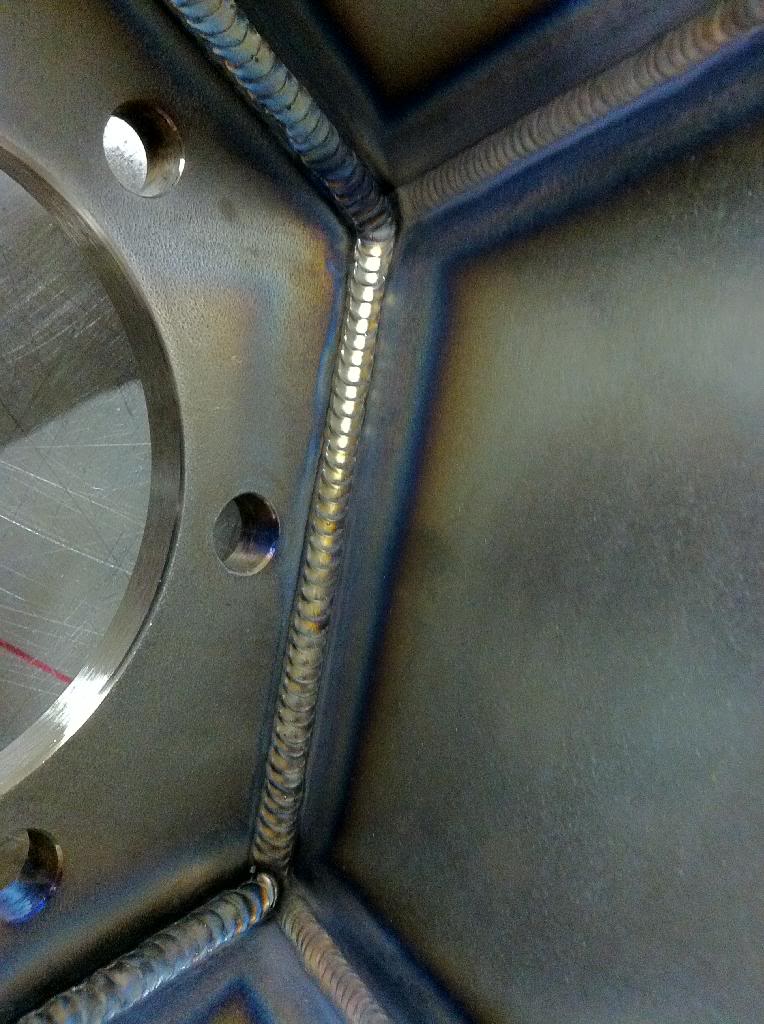

I had some 1" round stock and I have some heavy flatbar so spark up the new TIG welder!

I also had some 8mm drill rod that I welded on the top edge for smooth sliding.

I'm still working on the TIG welding, as you can see, not so pretty, but I think for a tool rest it will hold.

Yeah the welding is a bit rough, but I'll get better the more I do.

I can crank that new TIG welder up to 250 Amps and really weld some thick stuff, here I was at about 200Amps and I had to move fast or melt stuff too much!

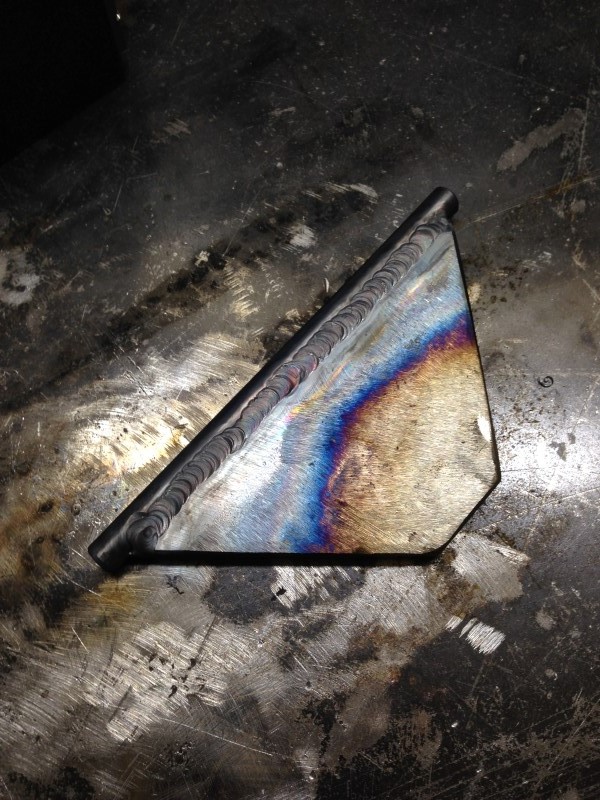

That is all the welding done, now I just need to clean it up a bit.

Cleaned up and ready for it's maiden voyage!

I sure do love having my own tools etc on hand!

but I often find it too large for some things, I'd love to get the 6" and the 4" but they cost a bit $53 and $49 respectively and shipping is not cheap as they are heavy, plus I'd live to have one like..... today

I had some 1" round stock and I have some heavy flatbar so spark up the new TIG welder!

I also had some 8mm drill rod that I welded on the top edge for smooth sliding.

I'm still working on the TIG welding, as you can see, not so pretty, but I think for a tool rest it will hold.

Yeah the welding is a bit rough, but I'll get better the more I do.

I can crank that new TIG welder up to 250 Amps and really weld some thick stuff, here I was at about 200Amps and I had to move fast or melt stuff too much!

That is all the welding done, now I just need to clean it up a bit.

Cleaned up and ready for it's maiden voyage!

I sure do love having my own tools etc on hand!