David Agnew

Member

- Messages

- 285

Morning, all.

This idea may, or may not, even come to fruition, but I'd enjoy having others' insights.

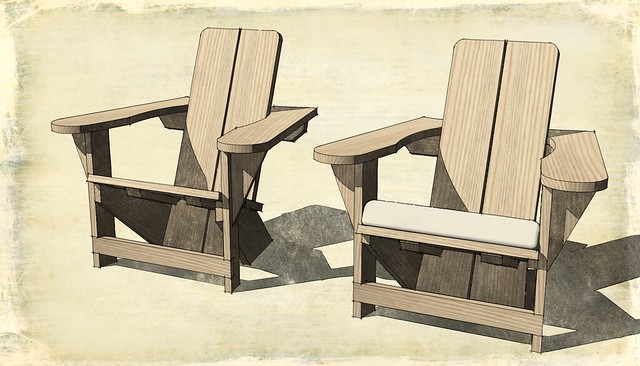

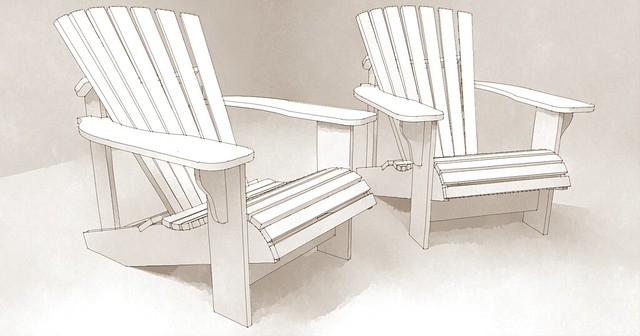

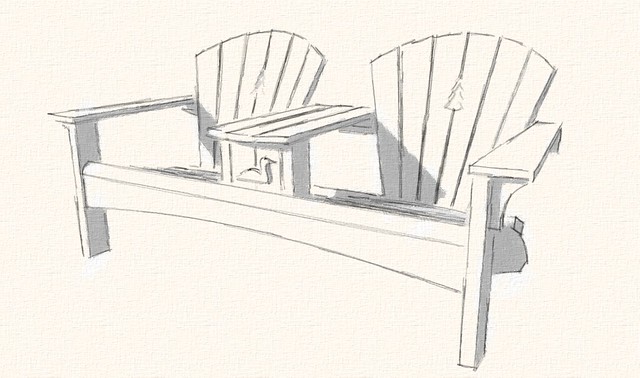

I've had a stack of 2x6 and 2x8 pressure treated pine sitting in my garage for a little over year now.... leftover from a deck building project. I was brainstorming ways to get rid of it and thought of Adirondack chairs. Having never built one before, I began researching. It appears there are two major design types, the classic form with the back supported by the arms and a newer style with vertical stretchers triangulating the back, arm, and base.

Which is strongest?

My problem is that many of the folks in my extended family are large. Quite large. Adirondack chairs are low to the ground... I can easily imagine one of my 350 lb cousins putting one hand on an arm-rest, bending, rotating, then levering into the chair and flopping down the last foot to get into the low seat. And having the back break free from the arms...

These chairs would be outdoors 24/7/365 through midwestern winter and summer. -5*F to 105*. Rain, snow, and scorching sun. So I assume fastener joinery will be required rather than stronger mortise & tenon or half-laps and things due to wood movement.

Any insights, plans, or experiences are appreciated. Thanks.

This idea may, or may not, even come to fruition, but I'd enjoy having others' insights.

I've had a stack of 2x6 and 2x8 pressure treated pine sitting in my garage for a little over year now.... leftover from a deck building project. I was brainstorming ways to get rid of it and thought of Adirondack chairs. Having never built one before, I began researching. It appears there are two major design types, the classic form with the back supported by the arms and a newer style with vertical stretchers triangulating the back, arm, and base.

Which is strongest?

My problem is that many of the folks in my extended family are large. Quite large. Adirondack chairs are low to the ground... I can easily imagine one of my 350 lb cousins putting one hand on an arm-rest, bending, rotating, then levering into the chair and flopping down the last foot to get into the low seat. And having the back break free from the arms...

These chairs would be outdoors 24/7/365 through midwestern winter and summer. -5*F to 105*. Rain, snow, and scorching sun. So I assume fastener joinery will be required rather than stronger mortise & tenon or half-laps and things due to wood movement.

Any insights, plans, or experiences are appreciated. Thanks.

It's in some very, very fine print at the bottom of the Forum Rules.

It's in some very, very fine print at the bottom of the Forum Rules.