Jeff Horton

Member

- Messages

- 4,272

- Location

- The Heart of Dixie

Thinking about motor mounts for the Great Pumpkin. Tossed a couple of ideas around. I don't have a lot of machines on mobile bases but I was think as heavy as this is and as big as it is, it might be nice to able move it without resorting to the lift. And it would be nice to be able to move it out in the open space if I had a lot of jointing to do.

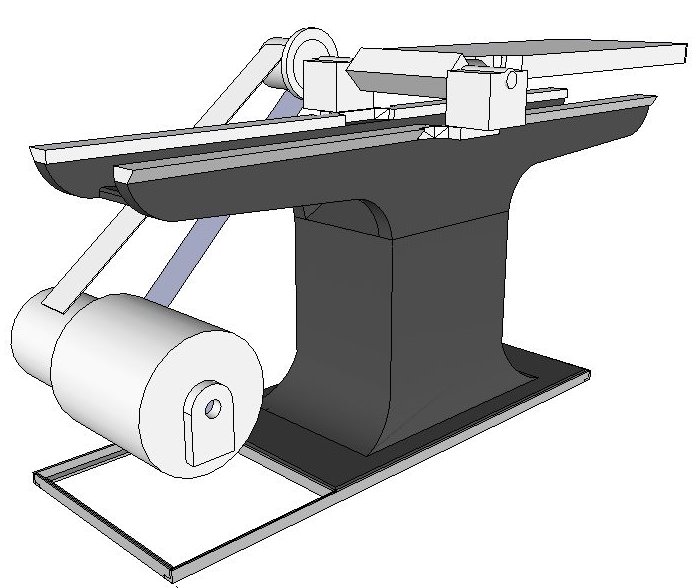

If I go with a base I can mount my motor on it. Take heavy angle welded together and add casters. Then just extend the frame out, add a nice looking wood slab and bolt it to the frame. Then bolt the motor to it. Looks like it should work to me. Anyone see anything I am missing?

If I go with a base I can mount my motor on it. Take heavy angle welded together and add casters. Then just extend the frame out, add a nice looking wood slab and bolt it to the frame. Then bolt the motor to it. Looks like it should work to me. Anyone see anything I am missing?

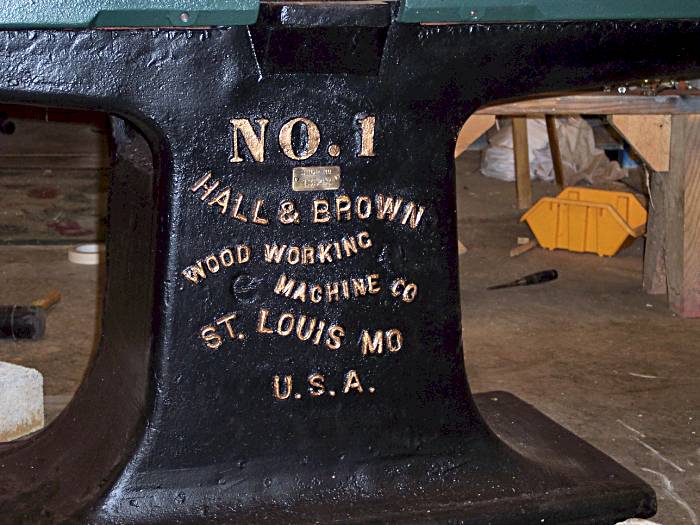

I was busy looking at the nice big jointing surface

I was busy looking at the nice big jointing surface