glenn bradley

Member

- Messages

- 11,547

- Location

- SoCal

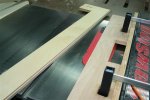

I felt bad about the mean things I have said about my original "beater" dado jig. I only had one last jig planned to make before getting back to other things but, decided to sneak this one in as well. So I give you version 2.0. Like my original version seen here, I use a template guide instead of relying on the outer edge of the router plate. I cut the ledge for the template bushing a bit extra deep so that the router will create a 'zero' edge on the first pass. I also cut a whompin' rabbet to accept the eemerson tools AIO (all in one) clamp. The not-often used DRO on my router table comes in handy for geting the depth right when making multiple stepped passes.

.

.

Here's the fixed and adjustable fences with the connector plates and clamp setting around. The connector plates get fixed to the fixed fence. The adjustable fence has slots and is fastened in place with carriage bolts and star knobs.

.

.  .

.

I modify a few 1/4" flat head machine screws to fit the odd slots on the AIO clamp. The flats keep the screw from turning in the slot. I slide the screws in and set the jig onto the clamp and fasten it in place with some small round knobs.

.

.  .

.

cont'd . . .

.

.

Here's the fixed and adjustable fences with the connector plates and clamp setting around. The connector plates get fixed to the fixed fence. The adjustable fence has slots and is fastened in place with carriage bolts and star knobs.

.

.  .

.

I modify a few 1/4" flat head machine screws to fit the odd slots on the AIO clamp. The flats keep the screw from turning in the slot. I slide the screws in and set the jig onto the clamp and fasten it in place with some small round knobs.

.

.  .

.

cont'd . . .

Last edited: