Stuart Ablett

Member

- Messages

- 15,917

- Location

- Tokyo Japan

Well this one will be filed under the heading of "Obligation".

The local neighbourhood association recently bought about a dozen of these tables....

They use them for meetings and such, they will stack one behind the other with the top tipped up and save space in the room that is used for meetings etc. The old tables had to be folded up and then carried out of the room. Most of the folks who use the tables and the room are older and this table set up and take down for each meeting was something they did not want to do anymore, fair enough.

They bought a dozen or so of these spiffy new tables in May this year, they were EXPENSIVE but they should last for many years. The old tables were rather battered and well used so it was time to replace them I guess.

Well someone did not unlatch the locks on the wheels of one table and with the table top flipped up pushed the table to move it and over it went. It landed on the leg of another table

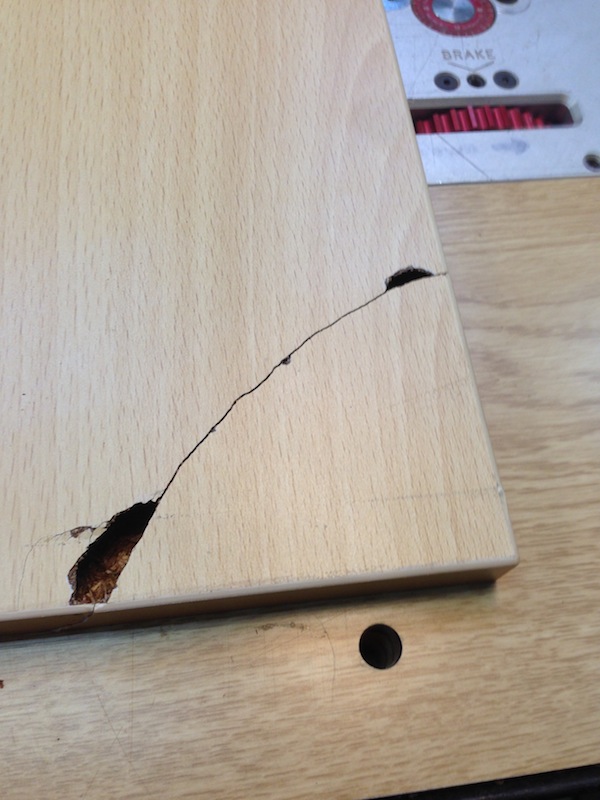

See the far corner?

A close up.

OK now what? No way I can just cut another piece of MDF and get this same veneer, I looked around, but this stuff is a plastic stuff that is about paper thin, and applied at the factory, so matching it is out of the question. Oh did I mention that they also want to spend as little money as possible?

I'm going to try to fix it, but how?

What I did was carefully pick out the particle board pieces from each side so I had just the edges to deal with.

Kind of hollowed it out.

Like this.

Next I built a corner frame so to speak, I used some of the left over white stock from building those shelves in the L shop, they have a thin removable plastic film on them so they should not stick to the table top I'm fixing.

I then mixed up some epoxy and thinned it with alcohol, which makes the epoxy pour almost like water. As you can imagine the hollowed out particle board soaked up a lot of this epoxy, but in the end I was able to fill the cavity to almost the top. When you thin the epoxy with alcohol it takes a LOT longer to cure.

As you can see there are some holes in my top, I bought some of these blocks of colored shellac that are used to fix dings in flooring etc, and I'll try my best to match up the colors, that will be next.

Wish me luck.

Cheers!

The local neighbourhood association recently bought about a dozen of these tables....

They use them for meetings and such, they will stack one behind the other with the top tipped up and save space in the room that is used for meetings etc. The old tables had to be folded up and then carried out of the room. Most of the folks who use the tables and the room are older and this table set up and take down for each meeting was something they did not want to do anymore, fair enough.

They bought a dozen or so of these spiffy new tables in May this year, they were EXPENSIVE but they should last for many years. The old tables were rather battered and well used so it was time to replace them I guess.

Well someone did not unlatch the locks on the wheels of one table and with the table top flipped up pushed the table to move it and over it went. It landed on the leg of another table

See the far corner?

A close up.

OK now what? No way I can just cut another piece of MDF and get this same veneer, I looked around, but this stuff is a plastic stuff that is about paper thin, and applied at the factory, so matching it is out of the question. Oh did I mention that they also want to spend as little money as possible?

I'm going to try to fix it, but how?

What I did was carefully pick out the particle board pieces from each side so I had just the edges to deal with.

Kind of hollowed it out.

Like this.

Next I built a corner frame so to speak, I used some of the left over white stock from building those shelves in the L shop, they have a thin removable plastic film on them so they should not stick to the table top I'm fixing.

I then mixed up some epoxy and thinned it with alcohol, which makes the epoxy pour almost like water. As you can imagine the hollowed out particle board soaked up a lot of this epoxy, but in the end I was able to fill the cavity to almost the top. When you thin the epoxy with alcohol it takes a LOT longer to cure.

As you can see there are some holes in my top, I bought some of these blocks of colored shellac that are used to fix dings in flooring etc, and I'll try my best to match up the colors, that will be next.

Wish me luck.

Cheers!