Cynthia White

Member

- Messages

- 3,220

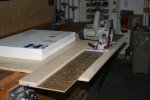

I have the Bosch 4100 Contractor's Table Saw or whatever it was called when I got it 4 years ago. When I finish what I'm working on (built-in bookcases), the next projects in the foreseeable future are all cabinets, built-ins everywhere. The Bosch has been great, but it's small, and it does get bogged down in hardwoods regularly. Just this week I discovered that my fence creeps away from the blade after many passes, so now I have to clamp the fence down to be sure it doesn't move. My biggest problem is handling sheet goods. I have to (obviously) break them down into manageable pieces before I can carry them to the Bosch. So I've been thinking I really need a real full-sized table saw. But then I was thinking maybe the Festool track saw would solve most of my problems at least with sheet goods, and I wouldn't have to cut everything twice.

What does my esteemed audience think?

What does my esteemed audience think?