glenn bradley

Member

- Messages

- 11,558

- Location

- SoCal

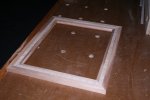

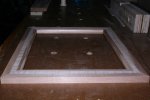

Last minute surprise; LOML has a picture to give to her SIL for Christmas. I have been bound and determined to make something useful out of a piece of rough, oddly figured mahogany that hides in my "interesting" stock area. No real plan here so you'll just have to trust me on the action shots and wait to see what I am trying to do till the end. Why not? Its not like you should be out in the shop working on your Christmas gifts or anything, right?

I want some thin strips off the side of this curly maple board. Its a nice piece of stock so I don't want to mill the whole thing down for the few small pieces I want but, I do want them from the side and need them a specific width.

I rip off a couple of 1/8" slices on the bandsaw and then rip them to rough width. Its kind of like resawing in miniature.

.

.  .

.

Here's the odd piece of mahogany.

cont'd

I want some thin strips off the side of this curly maple board. Its a nice piece of stock so I don't want to mill the whole thing down for the few small pieces I want but, I do want them from the side and need them a specific width.

I rip off a couple of 1/8" slices on the bandsaw and then rip them to rough width. Its kind of like resawing in miniature.

.

.  .

.

Here's the odd piece of mahogany.

cont'd

Last edited: