Robert Gorham

Member

- Messages

- 3

- Location

- Montreal , Quebec , Canada

The use of T nuts and a track provides great functionality in many purchased and home made jigs, providing for easy positioning and securing of components, movable travel stops, hold downs and other valuable uses. I enjoy looking at the pictures and write-ups on the large variety of ingenious jigs that appear on this and other woodworking forums. They almost all incorporate one or more metal T tracks to enhance their functionality.

I too have made many jigs incorporating t-nuts but have never used a metal T track. I use a T slot router bit to cut the slots directly into the jig material. I use a 5/16” straight cutter bit and rout a dado 3/8” deep using 2 or three passes and then finish with 1 pass of the T slot bit set to match the 3/8” depth. For my jigs I use either Baltic Birch or hardwoods such as maple or oak and have never had one fail on me as in breaking the slot when torquing down hard on a hold down for instance.

From a cost standpoint you save on not purchasing the T track and producing one is quicker than grooving, fitting and screwing down the metal T track. If you are less than satisfied with your jig and decide to make a new “improved” one, your losses will be less as once you cut the metal track it may not be long enough or suitable for the revised jig.

The bit I use was purchased from Lee Valley Tools and I am sure that there are other sources for the same kind of bit. For those of you into making your own jigs this might be of interest.

Pictures attached

1: The T-Slot bit (picture taken from Lee Valley Website)

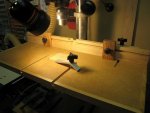

2: Drill press table (T slots for fence positioning, hold downs and fence stops)

3: Close up of the end of the T slot

4: Table saw cross cut jig (T slots for fence positioning and hold downs) Some of you have no doubt seen this jig on the internet; useful at times.

I too have made many jigs incorporating t-nuts but have never used a metal T track. I use a T slot router bit to cut the slots directly into the jig material. I use a 5/16” straight cutter bit and rout a dado 3/8” deep using 2 or three passes and then finish with 1 pass of the T slot bit set to match the 3/8” depth. For my jigs I use either Baltic Birch or hardwoods such as maple or oak and have never had one fail on me as in breaking the slot when torquing down hard on a hold down for instance.

From a cost standpoint you save on not purchasing the T track and producing one is quicker than grooving, fitting and screwing down the metal T track. If you are less than satisfied with your jig and decide to make a new “improved” one, your losses will be less as once you cut the metal track it may not be long enough or suitable for the revised jig.

The bit I use was purchased from Lee Valley Tools and I am sure that there are other sources for the same kind of bit. For those of you into making your own jigs this might be of interest.

Pictures attached

1: The T-Slot bit (picture taken from Lee Valley Website)

2: Drill press table (T slots for fence positioning, hold downs and fence stops)

3: Close up of the end of the T slot

4: Table saw cross cut jig (T slots for fence positioning and hold downs) Some of you have no doubt seen this jig on the internet; useful at times.

![DSCN1027 [800x600].jpg DSCN1027 [800x600].jpg](https://familywoodworking.org/forums/data/attachments/78/78340-45a1d4987dcb0d24b97604c25dc1a8da.jpg)

![DSCN1030 [800x600].jpg DSCN1030 [800x600].jpg](https://familywoodworking.org/forums/data/attachments/78/78341-6d826969cc620964431f8d4deda9ed97.jpg)