my trip to HD-

I was there earlier today to get some plywood, it was too crowded in the kitchen section with only one person working, so I went back there just now.

There was no one to order or get estimate.

there were prices posted on board stating group a or b starting at 15 dollars per sq foot delivered, no installed.

Im ok with that, not even that concerned about what color laminate.

the woman helping me told me she isn't in that dept, but will find someone who can help me.

She brings over a woman who says she can help me.

first, this may be rude, but the woman had a beard. something I don't see often.

Her English was weak, making it difficult to understand when she mumbled something.

Next, she told me she was a "floating specialist", ok, she had no clue about anything about countertops.

When I say no clue, I mean absolutely zero, zilch, nada, it was so insulting to me that they pawned off this moron bearded idiot to me I wanted to punch someones lights out.

Finally, I had enough. I mean, really, I tell her laminate, 4 times she asked me if I wanted granite, quartz, corian, no, laminate, formica, and then we have nice granite, quartz, no m'am, I prefer something less expensive, laminate, formica, and this went on for a5 minutes.

I walked her over to the board with all the samples and asked which ones are the least expensive, nothing. I got nothing from her.

She didn't answer me and went back to the computer.

I hear her mumbling, granite, quartz, and I finally told her Im not sure what her specialty is, but it certainly isn't countertops.

When is the kitchen person available. tomorrow, around 11 she thinks.

so the floating specialist as she called herself, only proved to have one specialty. Ignorance. Actually 2 specialties, audacity to even suggest she might be able to help me.

maybe 3, she can get a job in the circus, forgive me whomever, but she had a thicker beard than me, and being a fatso, I don't make fun of people, but she has it coming to her.

We are in serious trouble if this is the new workforce in our country.

so I never got anywhere today.

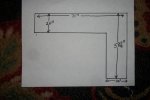

carol, Im good up to 350 -400 bucks, after that, Ill either try it myself, or make it out of maple or plywood and just stain it and be done.

(home depot is 1 mile from my home, so I figured good starting point)

Just as well, had you found anyone (in my store) they wouldn't have had a clue about what you were aking. Reminds me of the day I went into an HD and asked the young man in the tool department (he approached me asking to help) "Where are the biscuits?". Smiling, he pointed toward the front of the store, "Burger King is just across the street, I think they have biscuits".

Just as well, had you found anyone (in my store) they wouldn't have had a clue about what you were aking. Reminds me of the day I went into an HD and asked the young man in the tool department (he approached me asking to help) "Where are the biscuits?". Smiling, he pointed toward the front of the store, "Burger King is just across the street, I think they have biscuits".