Carol Reed

In Memoriam

- Messages

- 5,533

- Location

- Coolidge, AZ

Lottsa parts! I mean LOTTSA parts!

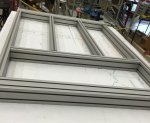

Got the gantry risers assembled today.

I am not disappointed with the robustness of these parts. The red parts are 1/4" powder-coated steel plate. The aluminum is the beefiest extrusion I have seen and there is more coming!

From the parts above I made the part below times two.

This is not a task for a dyslexic person! I needed a right and left and I had parts laid out every where. Did make one miscue and had to disassemble one piece and reassemble on the other face of the plate!

After I got home and looked my my pictures, I realized I failed to take one of the TWO gantry risers completed. I did all I could do today. This was one of the five boxes that did arrive. The rails won't arrive until next weekend, so likely won't get back to it until next weekend.

Previous builders of this machine have raved about the packaging. I concur. First the boxes were sturdy and every flap was taped tight. Parts inside were separately bagged with plenty of packing material to keep things in place. Each box is a separate assembly, so when you build that assembly, there should no parts leftover. Such was the case here.

It was a good day today!

Got the gantry risers assembled today.

I am not disappointed with the robustness of these parts. The red parts are 1/4" powder-coated steel plate. The aluminum is the beefiest extrusion I have seen and there is more coming!

From the parts above I made the part below times two.

This is not a task for a dyslexic person! I needed a right and left and I had parts laid out every where. Did make one miscue and had to disassemble one piece and reassemble on the other face of the plate!

After I got home and looked my my pictures, I realized I failed to take one of the TWO gantry risers completed. I did all I could do today. This was one of the five boxes that did arrive. The rails won't arrive until next weekend, so likely won't get back to it until next weekend.

Previous builders of this machine have raved about the packaging. I concur. First the boxes were sturdy and every flap was taped tight. Parts inside were separately bagged with plenty of packing material to keep things in place. Each box is a separate assembly, so when you build that assembly, there should no parts leftover. Such was the case here.

It was a good day today!

Last edited:

That's a mixed bag! On a good note, recently I had a package that showed delivered from FedEx, a 120# workbench kit, when I wasn't home. Tracking showed left at front door. Well it sure wasn't there! Turns out the driver had carried it into my shop (door was not locked) for me because it was raining!! I need to order something and ship with them so I can get him back out here to give him a tip!!

That's a mixed bag! On a good note, recently I had a package that showed delivered from FedEx, a 120# workbench kit, when I wasn't home. Tracking showed left at front door. Well it sure wasn't there! Turns out the driver had carried it into my shop (door was not locked) for me because it was raining!! I need to order something and ship with them so I can get him back out here to give him a tip!!