- Messages

- 16,579

- Location

- Reno NV

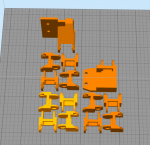

Did a bit of cleanup on the wiring and appearance of my printer.

I'd found an enclosure on thingiverse I liked, but it really didn't work for the components I wanted.

So I pulled it into sketchup and redid it. In the end, I should have just taken the design and started from scratch, which is pretty much what I did.

I created a case to hold the control board, a mosfet, and a raspberry pi.

I also added a little 5v power supply to provide power to the raspberry pi.

Also put a fan on the control board, just because.

I still need to work the wires around and create a custom shorter usb cable for the pi->control board, but will tackle those another day.

I've got a wide angle pi camera coming, so will have to take the cover off and work on adding that to printer.

And I've got my auto level sensors coming soon. So still a little bit of wire work to do, but I'm liking how this worked out.

So now I have a printer that takes one power cord and I can connect to and control over the lan using octopi.

I'd found an enclosure on thingiverse I liked, but it really didn't work for the components I wanted.

So I pulled it into sketchup and redid it. In the end, I should have just taken the design and started from scratch, which is pretty much what I did.

I created a case to hold the control board, a mosfet, and a raspberry pi.

I also added a little 5v power supply to provide power to the raspberry pi.

Also put a fan on the control board, just because.

I still need to work the wires around and create a custom shorter usb cable for the pi->control board, but will tackle those another day.

I've got a wide angle pi camera coming, so will have to take the cover off and work on adding that to printer.

And I've got my auto level sensors coming soon. So still a little bit of wire work to do, but I'm liking how this worked out.

So now I have a printer that takes one power cord and I can connect to and control over the lan using octopi.

Last edited: