- Messages

- 11,632

- Location

- Constantine, MI

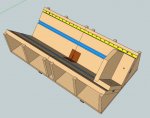

I'm working on a small box with mitered corners and I want to add splines for both strength and aesthetics. I'll need to build a jig and I know these can be done either on the router table or table saw but I was curious as to which might be the better choice. Since I have yet to build the jig I am open to either.

What might be the advantages/disadvantages to each method? Which is safer? Which is easier to control? Does using a router bit insure that you will have a flat bottomed grove?

What does the collective say?

What might be the advantages/disadvantages to each method? Which is safer? Which is easier to control? Does using a router bit insure that you will have a flat bottomed grove?

What does the collective say?

I agree on the fence and thin spline points. However...

I agree on the fence and thin spline points. However...