...but I was wondering how it attaches to a bench or table. I have looked on their site and either miss it or its not there. I know some of you here have it so I thought I would find out. I am looking at the D4R if it makes any difference on the model...

I have the D4, not the D4R. They are almost identical, though.

In the User Guide, on Page 11, Figure 1-22, you will find exactly what I did, to raise the jig to a better working position. You also will find Chapter 1 at:

http://leighjigs.com/data/D4R-Ch01.pdf .

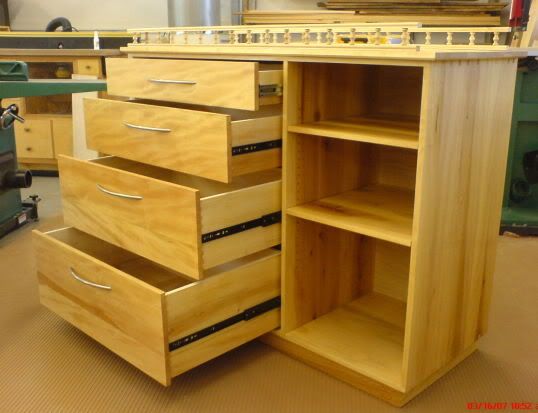

In addition, for a particular project I did some time ago, I had to raise the jig even more, to allow me to route pins and tails on 50-inch long boards - here you see the D4 sitting on the dovetail box I made for it:

THIS is one of the boards I was talking about

:

And yet another board, etting ready to cut the sliding dovetail socket - this photo also shows the box supporting the D4:

The project was this changing table for our daughter, who was getting ready for our #5 granddaughter - and the boards were to assemble the carcass for the table:

The partition is a sliding dovetail, also made on the D4, of course:

Enjoy!

.