Aaron Beaver

Member

- Messages

- 427

- Location

- Missouri

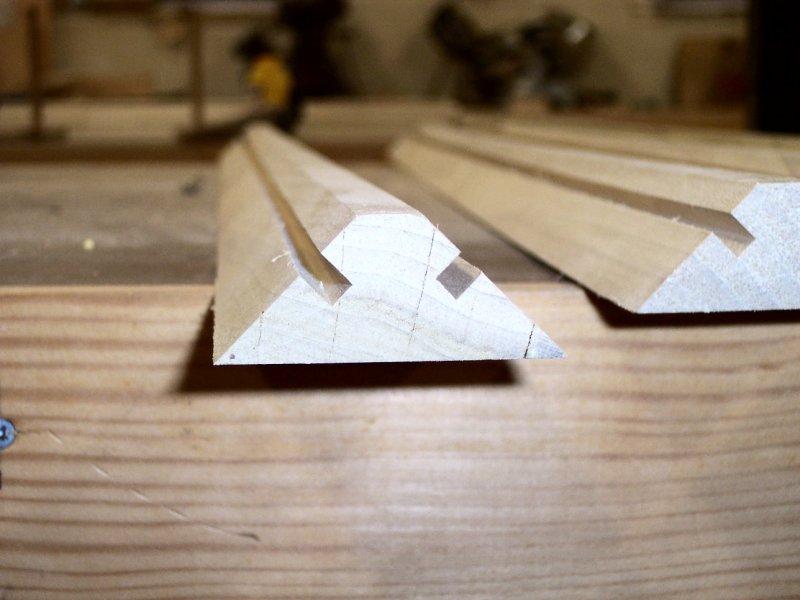

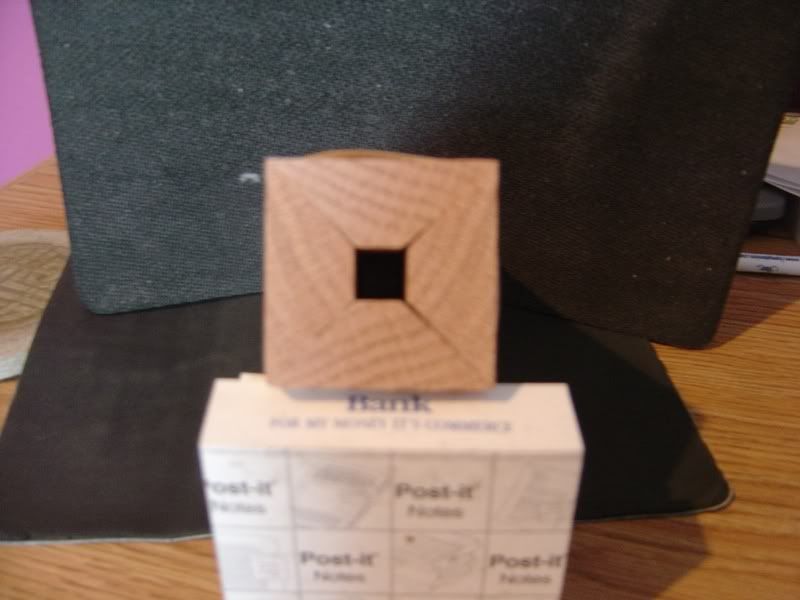

Here is a picture of a test I did, the test pieces are only about 6 inches long, where the real leg will be much longer.

As you can see there are some gaps along the 45's at the inside. I do believe this is from me not holding the piece tight enough against the fence.

Anyway the outsdie corners look fine and when I measured the diagonals they were spot on. Also the real legs will have splines in the 45's as well. Even with the mess up and since the inside will be hidden once done, do you think this would be okay if it happens on the larger legs. The other legs are going to be 2 1/4" square when put together, and 49" tall.

Just so you know, I checked everything on my table saw before I did this test in preperation for starting this project. Made sure the blade & miter slot were good with my dial indicator, same thing with the fence. I really think its because I didn't keep enough pressure against the fence, but this is my first time doing cuts like this.

As you can see there are some gaps along the 45's at the inside. I do believe this is from me not holding the piece tight enough against the fence.

Anyway the outsdie corners look fine and when I measured the diagonals they were spot on. Also the real legs will have splines in the 45's as well. Even with the mess up and since the inside will be hidden once done, do you think this would be okay if it happens on the larger legs. The other legs are going to be 2 1/4" square when put together, and 49" tall.

Just so you know, I checked everything on my table saw before I did this test in preperation for starting this project. Made sure the blade & miter slot were good with my dial indicator, same thing with the fence. I really think its because I didn't keep enough pressure against the fence, but this is my first time doing cuts like this.

You are absolutely correct.

You are absolutely correct.