- Messages

- 36,987

- Location

- ABQ NM

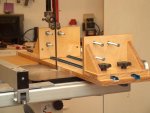

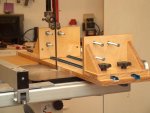

This came up in another thread, and I couldn't find that I'd posted it here before, so here are a few pics of a bandsaw sled and outfeed table I made a couple years ago.

The pics are pretty self explanatory...the sled is made of birch ply, with a UHMD plastic runner for the miter slot. The two "shoes" are mounted to t-tracks. I left the tracks a bit proud, so the shoes have dadoes to accommodate the tracks. It keeps the shoes from twisting. The shoes have sharpened bolts going through threaded inserts (which are mounted with screws) to hold odd-shaped pieces of wood. I use a hex socket on a power driver to tighten and loosen the bolts quickly.

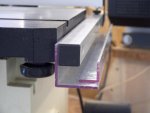

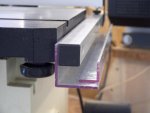

The outfeed table is pretty simple, with a little hippie engineering for the mount onto the bandsaw fence rail. I used threaded knobs to attach the table, so it can be removed quickly if necessary. (I've not yet had the need, though.) The support legs are adjustable with built-in turnbuckles (hidden by sliding covers made of scrap wood), and they have rare earth magnets in the bottoms top keep them in place on the mobile base. That way the table moves with the saw on the mobile base.

It works well for crosscutting and ripping small logs and odd-shaped turning blanks. The only caveat is that the saw needs to have the blade drift adjusted out as much as possible, to make the cut line as close as possible to the miter slot in the table. Otherwise, the blade either wants to curve into the sled or away from it.

Holler if you have any questions.

The pics are pretty self explanatory...the sled is made of birch ply, with a UHMD plastic runner for the miter slot. The two "shoes" are mounted to t-tracks. I left the tracks a bit proud, so the shoes have dadoes to accommodate the tracks. It keeps the shoes from twisting. The shoes have sharpened bolts going through threaded inserts (which are mounted with screws) to hold odd-shaped pieces of wood. I use a hex socket on a power driver to tighten and loosen the bolts quickly.

The outfeed table is pretty simple, with a little hippie engineering for the mount onto the bandsaw fence rail. I used threaded knobs to attach the table, so it can be removed quickly if necessary. (I've not yet had the need, though.) The support legs are adjustable with built-in turnbuckles (hidden by sliding covers made of scrap wood), and they have rare earth magnets in the bottoms top keep them in place on the mobile base. That way the table moves with the saw on the mobile base.

It works well for crosscutting and ripping small logs and odd-shaped turning blanks. The only caveat is that the saw needs to have the blade drift adjusted out as much as possible, to make the cut line as close as possible to the miter slot in the table. Otherwise, the blade either wants to curve into the sled or away from it.

Holler if you have any questions.