Dan Gonzales

Member

- Messages

- 511

- Location

- Whittier, CA, USA

I have a Dewalt DW746 hybrid table saw that has served me well. I have made two modifications to it (so far).

Fence Mod ------------------------------------------------------

It came with a single face that can be moved from one side to the other as needed. I rarely used the right side of the fence but it was annoying to move the face from one side to the other and clamping a sacrificial fence was difficult. I was also tired of small items falling off the fence arm. I was going to make a face from some MDF when I saw a brand new complete fence on eBay. Had a WOOHOO moment after winning it with the $20 initial bid.

I used the the face and the stud holding plate from the new fence and added screws and extension nuts. I will use the remaining fence assembly to build out a router fence system utilizing the table saw guide bars later.

1. Remove the fence faces from both fences.

2. Cut the studs back on one stud plate. Turn new threads on them. Place the extension nuts with Threadloc on them.

3. Pop the studs off the other stud plate.

4. Layout and drill holes on the new fence face.

5. Install original fence face, stud plate with extension nuts on left side of fence.

6. Install new fence with holes and the other stud plate with new screws on right side of fence.

7. Wiggle, align, square and tighten the new fence configuration.

Splitter Mod ----------------------------------------------------------

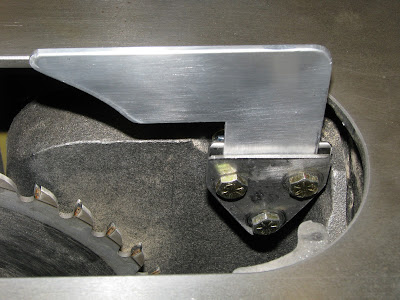

The safety device that came with the saw is the typical not quite right device that most manufactures send with their table saws, I removed it and never used it. After considering the kickback incidents I've experienced over my woodworking years I decided to make my own riving knife inspired by Bob Ross's BORK, but after speaking with him I realized there wasn't enough space behind the blade to accommodate a riving knife dropping into the casting below the table. So on to a simpler fitted splitter.

1. UNPLUG THE SAW!

2. Remove the blade and original splitter bracket.

3. Layout and drill third hole into the casting.

4. Tap the two existing holes and the new one for 1/4-28 threads. The original manufactures holes were nicely milled in cast bosses.

* Yes I just drilled into the iron casting, the decision was made after much careful thought regarding all consequences and it is a safe decision for me. It is 1/4" hole in the middle of a large 3/8" thick casting, the warranty expired 2 years ago and the screw to be used in this position is for alignment purposes only.

5. Make a template for the bracket plates. I like using milk bottle plastic, more durable than cardboard or paper.

6. Layout, cut and drill the bracket plates from stainless steel .125" sheet stock using a jig saw and drill press. I finished the shape with a file and Ridgid bench top sander. I flattened and polished the plates using wet/dry sanding paper.

7. I initially used c-nuts, they are a type of lock nut, for the bracket. But they really tore up the grade 2 screws I was using. I changed over to grade 8 hardware and jam nuts instead.

8. Assemble and install the brackets to rough alignment.

9. Measure, layout and cutout splitter blade. I used .110" 6061 sheet aluminum stock and did the cutting on my bandsaw. I finished using the wet dry paper and the Ridgid bench top sander. Final fitting was done with a file. The splitter goes through a cutout in the zero clearance insert, has shoulders that rest on the top two bracket screws and an alignment slot at the bottom that goes over the screw I drilled and tapped for. I made two splitters, one to handle cuts to 1 1/2" and one for full blade extension.

10. Measure, layout and cut the slot in the zero clearance insert. I muscled through it with a regular drill bit on the drill press and then realized I should have chucked and used a cutting bit from my rotary tool. Next time.

11. Install everything. Final fitting, tweaking and alignment. I placed a drop of white grease on the brackets to ease removing and installing the splitter.

Last thoughts:

* I made the decision to make these changes and assume my own risks. You should do the same when considering making changes to your power equipment.

* Fitting the shape of the splitter to the blade influenced my decision to use aluminum stock... just in case I crank the blade up a bit to far.

* I picked my raw material from the cutoff bins at my local metal dealer. Remember to take micrometers or calipers with you to be certain of the stock thickness. I prefer to use micrometers because the cutoff pieces often have deformed edges that the calipers can't reach over, plus they easily fit in my pocket.

* Total cost was about $23 for everything for the fence.

* Total cost was about $11 for everything for the splitter.

Fence Mod ------------------------------------------------------

It came with a single face that can be moved from one side to the other as needed. I rarely used the right side of the fence but it was annoying to move the face from one side to the other and clamping a sacrificial fence was difficult. I was also tired of small items falling off the fence arm. I was going to make a face from some MDF when I saw a brand new complete fence on eBay. Had a WOOHOO moment after winning it with the $20 initial bid.

I used the the face and the stud holding plate from the new fence and added screws and extension nuts. I will use the remaining fence assembly to build out a router fence system utilizing the table saw guide bars later.

1. Remove the fence faces from both fences.

2. Cut the studs back on one stud plate. Turn new threads on them. Place the extension nuts with Threadloc on them.

3. Pop the studs off the other stud plate.

4. Layout and drill holes on the new fence face.

5. Install original fence face, stud plate with extension nuts on left side of fence.

6. Install new fence with holes and the other stud plate with new screws on right side of fence.

7. Wiggle, align, square and tighten the new fence configuration.

Splitter Mod ----------------------------------------------------------

The safety device that came with the saw is the typical not quite right device that most manufactures send with their table saws, I removed it and never used it. After considering the kickback incidents I've experienced over my woodworking years I decided to make my own riving knife inspired by Bob Ross's BORK, but after speaking with him I realized there wasn't enough space behind the blade to accommodate a riving knife dropping into the casting below the table. So on to a simpler fitted splitter.

1. UNPLUG THE SAW!

2. Remove the blade and original splitter bracket.

3. Layout and drill third hole into the casting.

4. Tap the two existing holes and the new one for 1/4-28 threads. The original manufactures holes were nicely milled in cast bosses.

* Yes I just drilled into the iron casting, the decision was made after much careful thought regarding all consequences and it is a safe decision for me. It is 1/4" hole in the middle of a large 3/8" thick casting, the warranty expired 2 years ago and the screw to be used in this position is for alignment purposes only.

5. Make a template for the bracket plates. I like using milk bottle plastic, more durable than cardboard or paper.

6. Layout, cut and drill the bracket plates from stainless steel .125" sheet stock using a jig saw and drill press. I finished the shape with a file and Ridgid bench top sander. I flattened and polished the plates using wet/dry sanding paper.

7. I initially used c-nuts, they are a type of lock nut, for the bracket. But they really tore up the grade 2 screws I was using. I changed over to grade 8 hardware and jam nuts instead.

8. Assemble and install the brackets to rough alignment.

9. Measure, layout and cutout splitter blade. I used .110" 6061 sheet aluminum stock and did the cutting on my bandsaw. I finished using the wet dry paper and the Ridgid bench top sander. Final fitting was done with a file. The splitter goes through a cutout in the zero clearance insert, has shoulders that rest on the top two bracket screws and an alignment slot at the bottom that goes over the screw I drilled and tapped for. I made two splitters, one to handle cuts to 1 1/2" and one for full blade extension.

10. Measure, layout and cut the slot in the zero clearance insert. I muscled through it with a regular drill bit on the drill press and then realized I should have chucked and used a cutting bit from my rotary tool. Next time.

11. Install everything. Final fitting, tweaking and alignment. I placed a drop of white grease on the brackets to ease removing and installing the splitter.

Last thoughts:

* I made the decision to make these changes and assume my own risks. You should do the same when considering making changes to your power equipment.

* Fitting the shape of the splitter to the blade influenced my decision to use aluminum stock... just in case I crank the blade up a bit to far.

* I picked my raw material from the cutoff bins at my local metal dealer. Remember to take micrometers or calipers with you to be certain of the stock thickness. I prefer to use micrometers because the cutoff pieces often have deformed edges that the calipers can't reach over, plus they easily fit in my pocket.

* Total cost was about $23 for everything for the fence.

* Total cost was about $11 for everything for the splitter.