glenn bradley

Member

- Messages

- 12,234

- Location

- SoCal

I had mentioned in an earlier post that I wasn't satisfied with the bevel cuts I was getting on the CMS. This was on small, difficult to support hardwood pieces. Blade deflection that wasn't a problem on larger pieces became evident on the smaller work. Let's add a large dash of my inexperience here to be fair to the CMS.

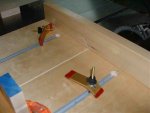

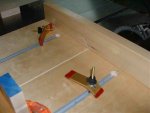

I've developed a method of sled building that I'm comfortable with and can knock out pretty quickly. I put together a small sled with hold downs to deal with the small pieces.

Parts -

Hold downs borrowed from the DP table -

Forstner holes at the ends of the t-track allow easy t-bolt insertion and removal -

You can see a couple larger sleds in the background of the second shot and as usual, my prowess as a photographer is evident .

.

I've developed a method of sled building that I'm comfortable with and can knock out pretty quickly. I put together a small sled with hold downs to deal with the small pieces.

Parts -

Hold downs borrowed from the DP table -

Forstner holes at the ends of the t-track allow easy t-bolt insertion and removal -

You can see a couple larger sleds in the background of the second shot and as usual, my prowess as a photographer is evident

Last edited:

I might need to "borrow" that idea for something down the road.

I might need to "borrow" that idea for something down the road.