- Messages

- 11,635

- Location

- Constantine, MI

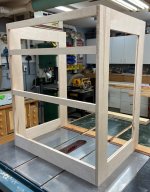

This cabinet is for the same client I built that huge pantry for a couple of months ago.

Straight forward piece, for the most part. The bottom drawer will hold water bottles - lots of them - so I'm going with 200 lb. slides and 5/8" BB ply for the strength and capacity.

Yesterday I was able to complete the hard maple frame. Love my new Domino! It makes assemblies like this so easy!

Giving some thought to using a single pocket hole screw at the center of the joints (each of the larger boards has two 8mm dominos) to hold the joint in place as the glue dries thereby eliminating the need to keep everything clamped up for several hours. Anyone ever try this?

Today I'll work on the MDF side panels and plywood top, bottom and back. The customer is providing a quartz counter top for this piece.

Straight forward piece, for the most part. The bottom drawer will hold water bottles - lots of them - so I'm going with 200 lb. slides and 5/8" BB ply for the strength and capacity.

Yesterday I was able to complete the hard maple frame. Love my new Domino! It makes assemblies like this so easy!

Giving some thought to using a single pocket hole screw at the center of the joints (each of the larger boards has two 8mm dominos) to hold the joint in place as the glue dries thereby eliminating the need to keep everything clamped up for several hours. Anyone ever try this?

Today I'll work on the MDF side panels and plywood top, bottom and back. The customer is providing a quartz counter top for this piece.