I currently have two of the Anet A8's that I've converted to metal frames (aka AM8). There were a lot of upgrades done to my printers to make them safer, more reliable, and more accurate. I haven't yet tried out one of the higher end printers ($2k & up), but I'm happy with how both of mine are working, so I guess ignorance is bliss.

I tried using Cura (version 3) for the first week, then saw some videos on Simplify3d. I had flashbacks to my experience trying to use various CNC software over the years, then trying Vectric, I wish I hadn't spent all that time on the other software. Simplify3d just seems to work so much better and has the features I need. Like Brent mentioned, there are some quirks with it's materials config that don't quite jive. I mostly like it's support creation features. I've printed parts sliced in cura and had the supports stuck to the piece, having to grind them off. Simplify3d's supports pop right off, they seem to cool just enough that the parts dont stick to them. Cura 4 has since come out, but I just don't want to learn another software when what I have works.

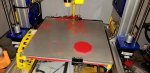

Speaking of materials, I mostly print with PLA and PETG, both are pretty safe to work with and don't require any venting. My office, where my printers live, is climate controlled, so I don't have enclosures for them. I have gotten where I turn down the heat in the winter in there, so if I'm doing some printing, I need to keep the temps up to about 70, otherwise I get some parts coming loose from the bed or warping, even with a heated bed. I also use borosilicate glass plates on my bed and some good old fashion aquanet hair spray. Parts stick to the bed really well while it's warm, as soon as the glass cools, the parts pop right off. If I'm in a hurry, I'll just pull the glass with the part and either stick it out in the cold or in the freezer and a minute later it pops right off.

One huge improvement for my printers, was the auto level feature. I'm using a capacitive sensor that moves in a grid patter on the bed to check for it being out of calibration. The firmware then adjusts my drawing to the bed to print correctly even when the bed is out of alignment. Brent's printer uses a BLTouch sensor, which has a retractable probe that physically touches the table, but works much the same.

There are several companies/individuals that sell the cheaper printers with all the safety, firmware, and feature upgrades done to them for about what you'd spend doing it yourself, so don't necessarily shy away from a certain printer because it is cheap or has some assembly required as someone may have a kit that has taken some of the assembly factor out of it.

Currently if I were to get another cheaper printer, I'd be looking at the Creality Ender 3. It's still got some assembly required, but not nearly as much as what the Anet and others have.

I don't want to overload you too much, so ask questions and I'll try to elaborate.

Oh, definitely get on Thingiverse. My id is

BuzzKc. I've got a bunch of collections, a few for Tools and the Workshop of items I've bookmarked.