- Messages

- 8,153

- Location

- The Gorge Area, Oregon

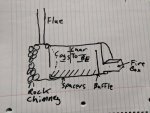

Finally got a chance to fire up the charcoal kiln I built some time back. It was dark by the time we closed it up so will probably have to wait until next weekend to see what's inside (it's at a friends property) which is kind of killing me with anticipation.

Loading it up, you can see the baffle that goes between the front and the wood leaning against it to the left. We used a mix of random shop off-cuts, cherry orchard branch trimmings, some maple scrap, and .. whatever that log we had was (elm I think).

Fired up, took about 30 minutes to really start to draw good... I think if I'd started with a smaller fire further back in the firebox it would've gone a bit faster maybe..

Smoking!

I didn't get a picture of the final smoke, pretty much clear and would light with kind of a roar when a flaming stick was put into it, but the flue is to big to sustain top combustion because the gas was to diffuse.

Loading it up, you can see the baffle that goes between the front and the wood leaning against it to the left. We used a mix of random shop off-cuts, cherry orchard branch trimmings, some maple scrap, and .. whatever that log we had was (elm I think).

Fired up, took about 30 minutes to really start to draw good... I think if I'd started with a smaller fire further back in the firebox it would've gone a bit faster maybe..

Smoking!

I didn't get a picture of the final smoke, pretty much clear and would light with kind of a roar when a flaming stick was put into it, but the flue is to big to sustain top combustion because the gas was to diffuse.