- Messages

- 789

- Location

- Central North Carolina

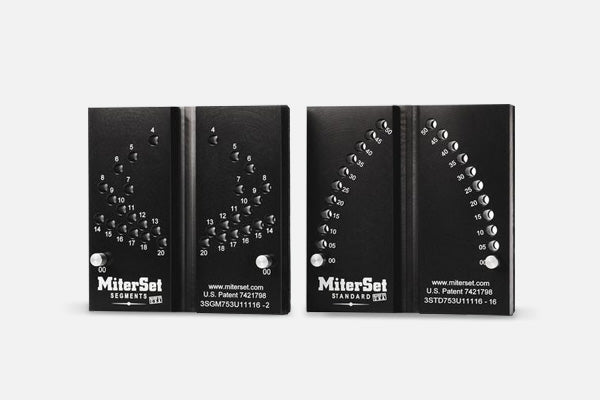

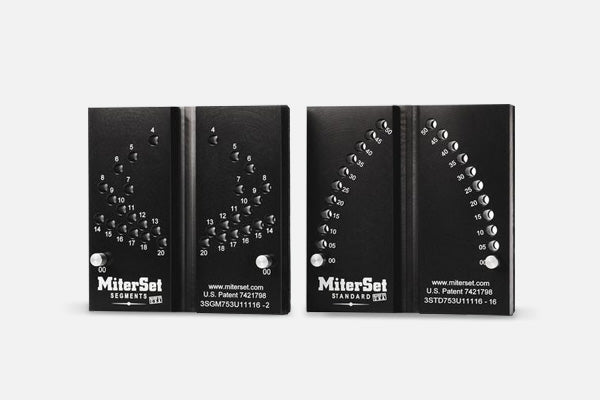

To get perfect angle cuts on segmented pieces, I use a MiterSet Segments Gauge. It gives me exact angle cuts for making segmented circles or partial circles. That and a reliable stop and clamp for the pieces as they are being cut to length will produce perfectly cut segments that all fit together without gaps. One only needs to set it for the number of segments desired. No math is involved. If you are going to be selling your lathe next year, I guess it's too late to be buying one of these, but it may help someone else. MiterSet also makes a similar gauge for setting precise angles in 1/2 degree increments in either direction from 90 degrees. I have both and have used them often. After buying these and trying them, I sold my Incra Miter Gauge and just use the OEM Delta miter gauges that I have.

This is the link for both, but they sell each one separately too. They are made to the quality of Aerospace Hardware and come in blow molded and padded plastic cases.

miterset.myshopify.com

miterset.myshopify.com

Charley

This is the link for both, but they sell each one separately too. They are made to the quality of Aerospace Hardware and come in blow molded and padded plastic cases.

MiterSet Package Set For Table Saws

Description MiterSet Standard MiterSet Segments You decided that you want both MiterSet products? That's great. Just add this bundle to your shopping cart. Set your miter gauge to precise angles in .5° increments with MiterSet Standard. And get the convenience of selecting the number of segments...

Charley