John Pollman

Member

- Messages

- 1,338

- Location

- Rochester Hills, MI

My K40 Laser just arrived today. But I'm also building a DIY CNC machine.

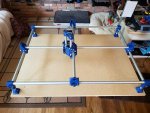

My DIY CNC machine is underway. I'm printing the final two printed parts. They will be done in about six hours. It's gonna be approximately 128 hours print time. I've already started assembling the basic frame components. This is gonna be fun!

My DIY CNC machine is underway. I'm printing the final two printed parts. They will be done in about six hours. It's gonna be approximately 128 hours print time. I've already started assembling the basic frame components. This is gonna be fun!