Keith Thomas

Member

- Messages

- 73

- Location

- florida

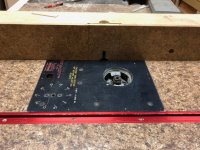

what ever router lift I have been using stopped moving up and down. Years ago I purchased a used Jessem rout r lift but never installed it. I don't even remember putting my old one in it seems that long ago so I'm not sure how I should do this.

I really need the router and can not afford to make a mistake in the only table I have or I will have to build a new table.

I have the template but no instructions. there is about 1/8" between the template and the Jessem router plate when its centered in the template. I have no idea how I did my last one. could some one throw me a clue?

Like does the plate need to be perfectly parallel with the fence or because its just a center point of a spinning bit it won't matter? And why is the template the size it is compared to the router plate? the plate is 14-3/4 by 11-3/4 and the template opening is 15x12. so does that mean I need a 1/4" bit or a 1/8" bit or what? I'm clueless. I've been watching videos but so far I'm lost.

I really need the router and can not afford to make a mistake in the only table I have or I will have to build a new table.

I have the template but no instructions. there is about 1/8" between the template and the Jessem router plate when its centered in the template. I have no idea how I did my last one. could some one throw me a clue?

Like does the plate need to be perfectly parallel with the fence or because its just a center point of a spinning bit it won't matter? And why is the template the size it is compared to the router plate? the plate is 14-3/4 by 11-3/4 and the template opening is 15x12. so does that mean I need a 1/4" bit or a 1/8" bit or what? I'm clueless. I've been watching videos but so far I'm lost.