- Messages

- 11,640

- Location

- Constantine, MI

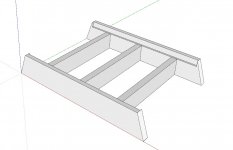

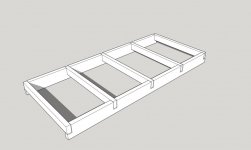

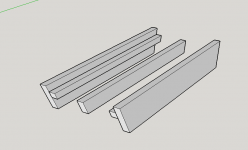

I'm working on a design for a bench for a client that wants it to be based on the Limbert design shown below. Not really a difficult build but something bothers me about those side panels. They at about 15" wide and it would seem that any effort to constrain them between two fixed legs would eventually result in the panels splitting. The only solution I can come up with is to build the leg, stretcher, and end panel as a fully ridged assembly and then have the plywood seat support 'float' between cleats attached to the stringers. A number of shorter cleats could be attached to the end panels as well. I think this would allow the ends to swell and shrink and the legs would just move in and out with them.

I think this solves the problem - anything I'm not seeing?

I think this solves the problem - anything I'm not seeing?

Last edited: