Dave Hall

Member

- Messages

- 5

- Location

- Victoria, BC Canada

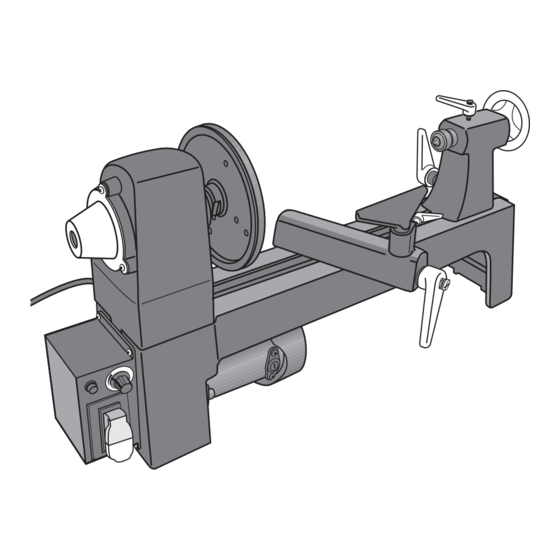

I recently purchased a used Mastercraft 12 inch mini Lathe. I tried it out finally yesterday and it was working fine.

I finished a first tst piece and added anothr piece of wood to practice on. When I turned the lathe on it blew the 15 amp breaker. I unplugged another item and tried to turn it on again. It blew the breaker again. I unplugged he lathe and reset the lathe using the reset button. I plugged it back in and turned it on. The breaker didn’t blow but now the lathe will not run.

Would the problem be the switch now or the reset button or the variable speed switch.

The switch has four poles on it and i am going to try and test it today but not sure how to do it??

Any thoughts???

I finished a first tst piece and added anothr piece of wood to practice on. When I turned the lathe on it blew the 15 amp breaker. I unplugged another item and tried to turn it on again. It blew the breaker again. I unplugged he lathe and reset the lathe using the reset button. I plugged it back in and turned it on. The breaker didn’t blow but now the lathe will not run.

Would the problem be the switch now or the reset button or the variable speed switch.

The switch has four poles on it and i am going to try and test it today but not sure how to do it??

Any thoughts???