- Messages

- 20,167

- Location

- Springfield, Missouri

I bought the mortiser that Sayer was selling a few weeks ago. Using my FILs mortiser of the same design was always a chore to make cuts with, and the bit screeched as the machine was running. Well, found that reading the manual helps.

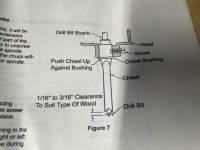

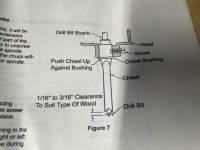

Having the bit 1/16” to 3/16” below the chisel makes a world of difference in the ease of cutting and eliminated the screeching noise.

The other thing was a mention of the extra 3 holes where the mortiser mounts to the base, they are for reversing the base and having more clearance for larger material.

Having the bit 1/16” to 3/16” below the chisel makes a world of difference in the ease of cutting and eliminated the screeching noise.

The other thing was a mention of the extra 3 holes where the mortiser mounts to the base, they are for reversing the base and having more clearance for larger material.