Aaron Beaver

Member

- Messages

- 427

- Location

- Missouri

Probably better, that would stop any rattles as well.putting space balls

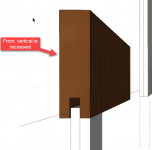

Kinda sounds like overkill to me -IMHO. Simply pinning each board at its centerline top and bottom should eliminate 99% of rattling and, so long as you spaced well, allow for expansion/contraction.I am going to use my Domino to attach each vertical to the rail, I would think that would keep them from rattling? Then the lap joints would just float/slide past each other for expansion.

Concur.Kinda sounds like overkill to me -IMHO. Simply pinning each board at its centerline top and bottom should eliminate 99% of rattling and, so long as you spaced well, allow for expansion/contraction.

You’ll have to excuse my inexperience but how would you pin these?Kinda sounds like overkill to me -IMHO. Simply pinning each board at its centerline top and bottom should eliminate 99% of rattling and, so long as you spaced well, allow for expansion/contraction.

simply take a small brad or "pin" and nail it though one side of the frame and into the slat at the top and bottom or like I said before just put the slat in the rails and place a space ball in between each one. This is an exampe of space balls.You’ll have to excuse my inexperience but how would you pin these?

I was cutting them to length to fit between the rails and use small dominoes to attach them to the rails. I probably just don’t know what pinning is so not sure how it’s done in this situation.

Ahhh. I see. Your plan will work, but I think it may be quite difficult to do so without having gaps at the top and bottom unless you are going to glue in the dominos and make each one, essentially, a mortice and tenon joint. Certainly would be strong.The issue is I wasn’t going to cut a groove in my rails to insert the verticals, planned on cutting them to length (distance between the top and bottom rails) and attaching with the domino, so I don’t think there is anyway to nail (pin) it, that I can see. Again I could just be missing it.

Appreciate the help.

a hard glued domino is not going to let this happen

Generally I do, although tape up the glue joints.Should I sand and apply finish to all these pieces prior to assembly?